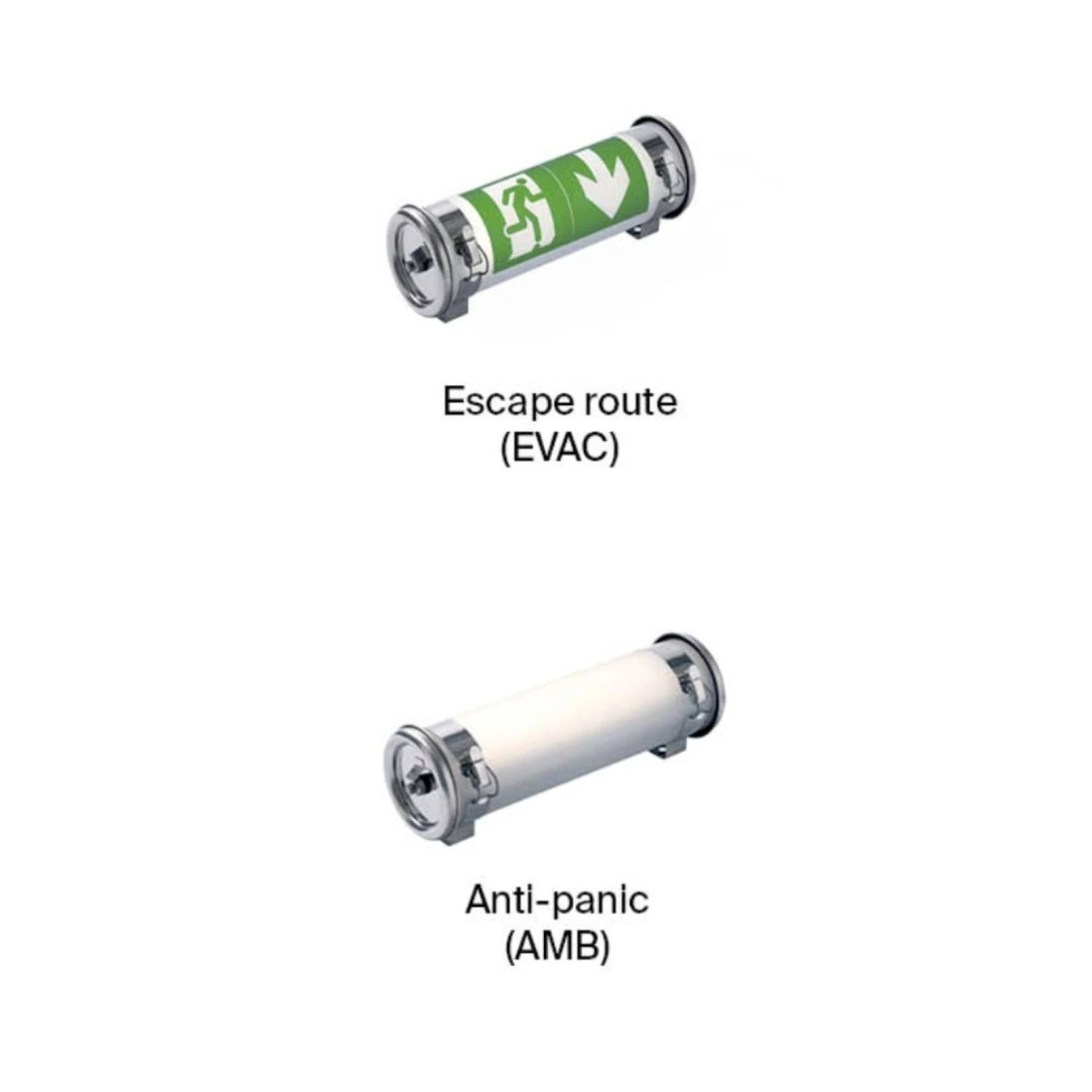

- Emergency lighting

- Very hot environments

- Clean rooms

- General lighting

- High ceilings

- Very cold environments

- Explosive area (ATEX)

- Emergency lighting

- Very hot environments

- Clean rooms

- General lighting

- High ceilings

- Very cold environments

- Explosive area (ATEX)

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Resistance to overvoltage and surges |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Resistance to overvoltage and surges |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Resistance to overvoltage and surges |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Resistance to overvoltage and surges |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Resistance to overvoltage and surges |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Resistance to overvoltage and surges |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Resistance to overvoltage and surges |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Resistance to overvoltage and surges |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |

| Operating temperature |

|---|

| Luminous flux |

| Service life |

| Warranty |

| Materials and diameter |

| Leaktightness & Resistance to IK shocks |

| Power supply (DC) |

| Lighting level management |

| Standards |

| Length |

| Colour temperature |

| Lighting efficiency |

| Optics & visual comfort |