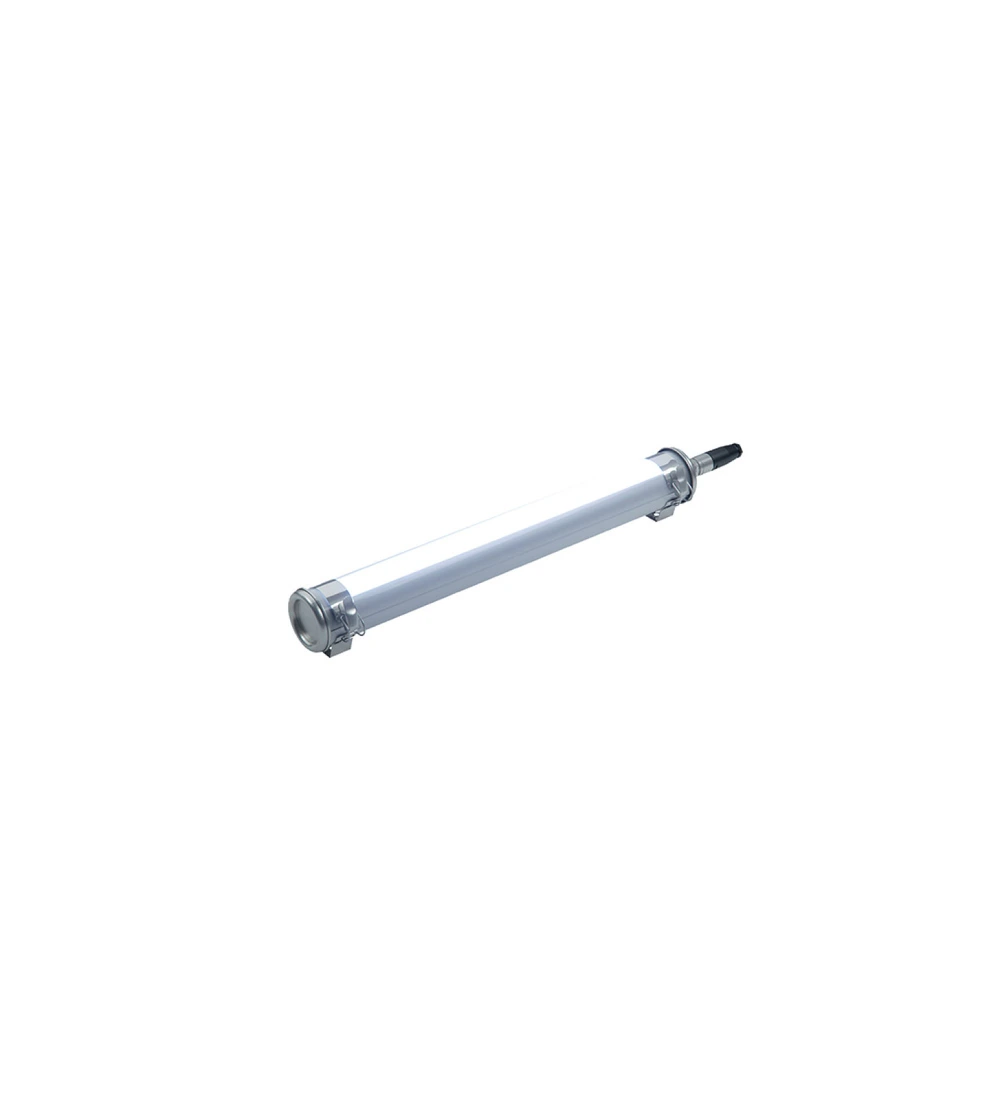

Leslie X-Heat

High temperature borosilicate glass tube ø133 for highly corrosive atmospheres

Industrial process lighting, up to 70°C

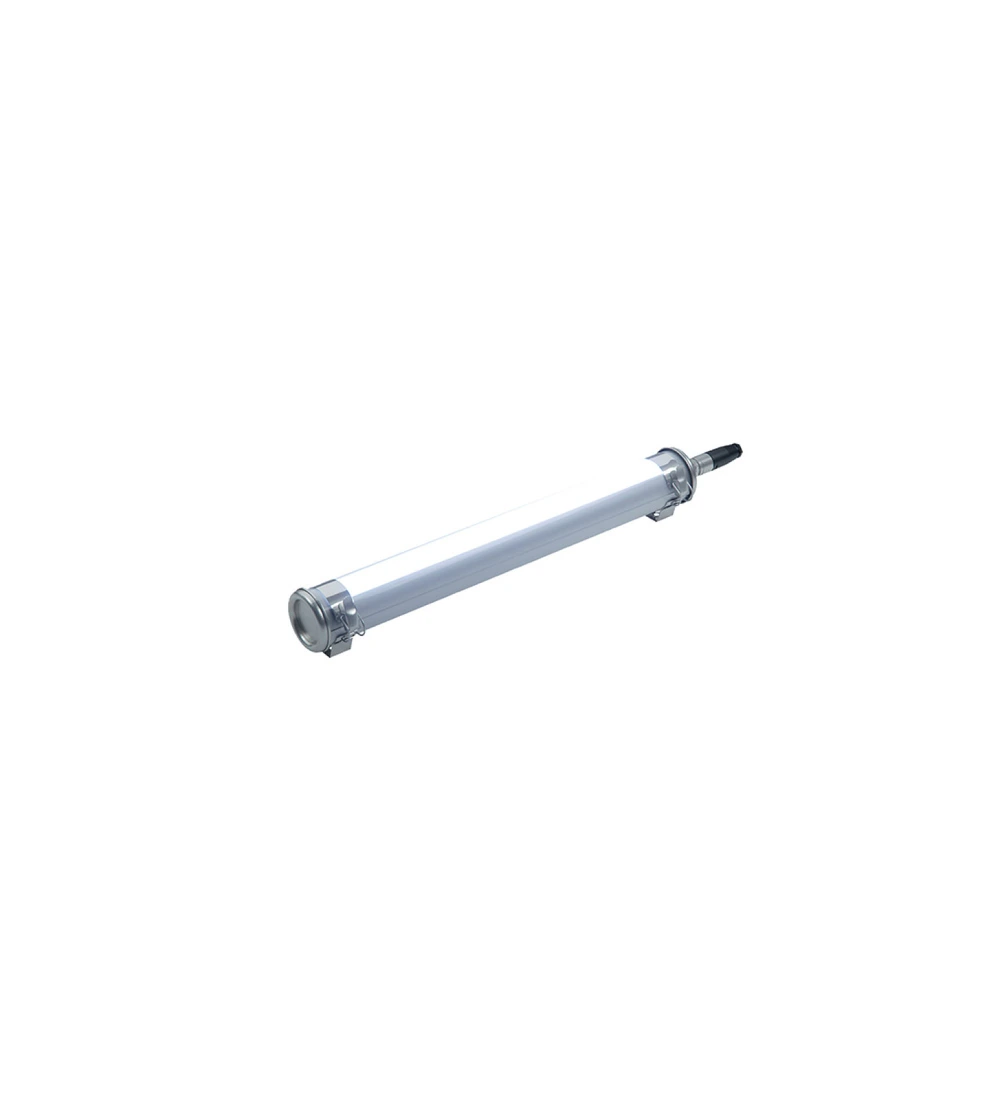

The Rankine luminaire is designed to light up small spaces dedicated to the most extreme industrial processes, bringing LED technology to the hardest-to-reach corners. This well-sealed, powerful and compact luminaire can withstand impacts, electrical disturbances and high temperatures up to 70°C.

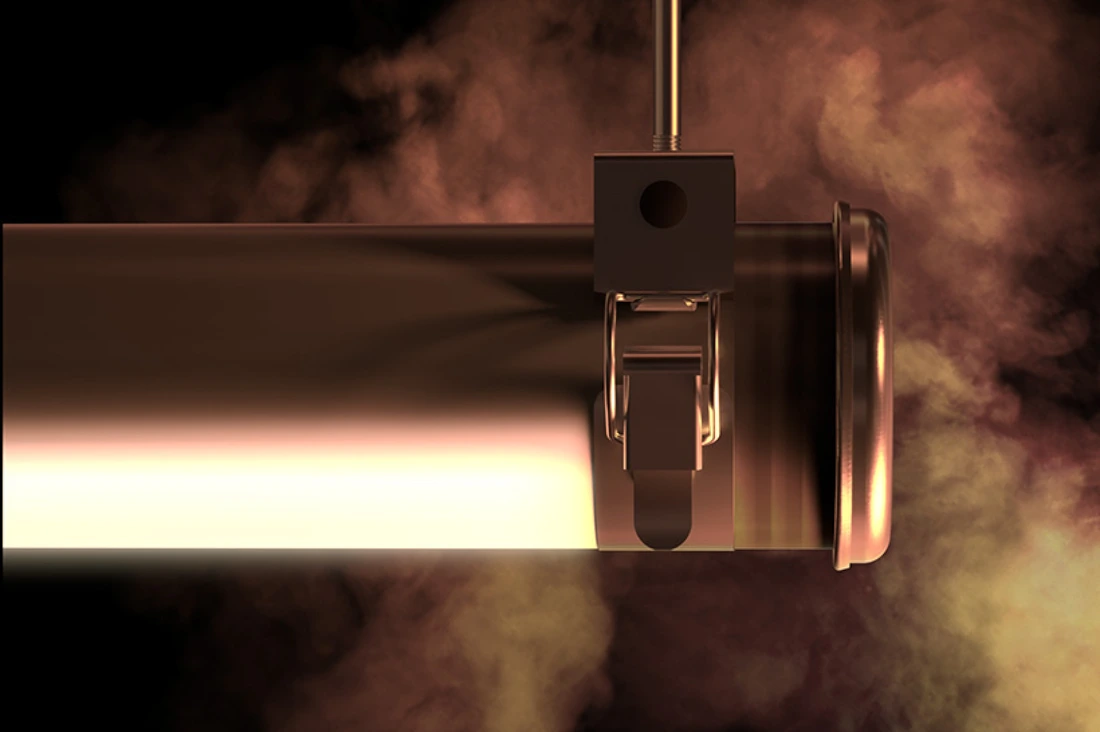

Corrosive substances, acid vapours

Oils & hydrocarbons

Dust and humidity

Washing with a high-pressure jet

Health and safety requirements according to IFS, BRC and HACCP texts

Permanent use at temperatures of up to 70°C

Repeated turning on and off

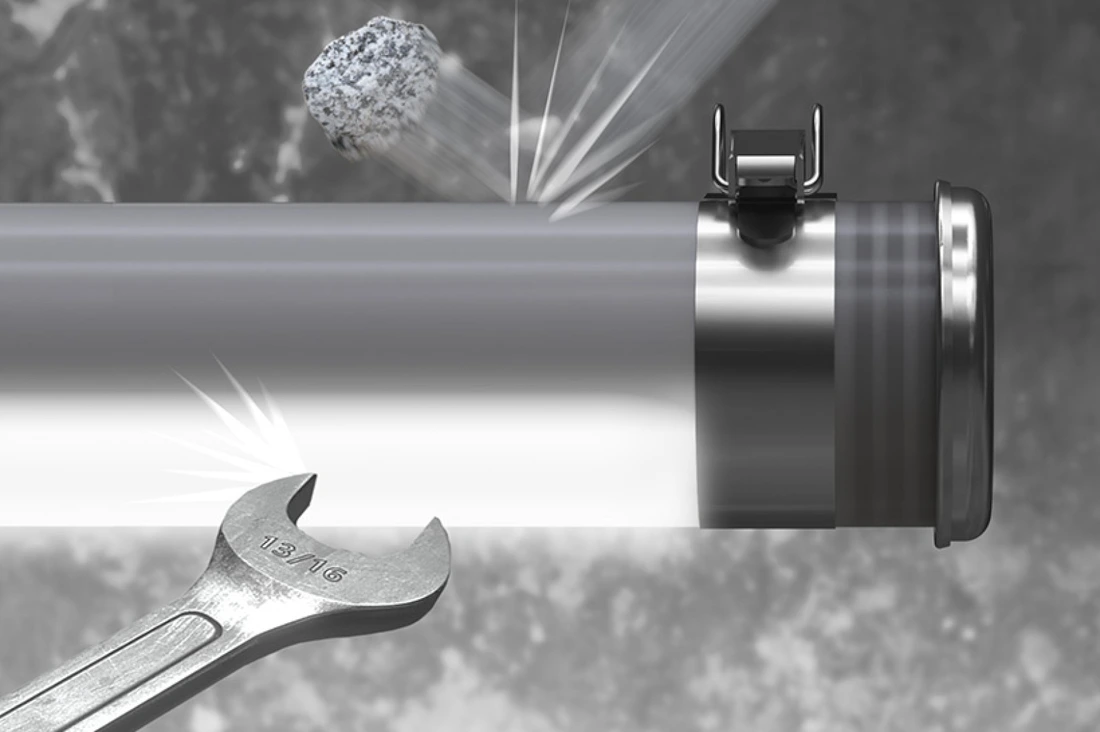

Heavy mechanical impacts

Intense and repetitive vibrations

The RANKINE is solid, compact and hermetically sealed thanks to its 3-seal system, reflecting Sammode’s expertise in high-temperature environments. The unique design of the internal head sink ensures a long life for the LED source, even when used 24/7 at 70°C.

The insulated internal electronics are specifically calibrated to limit heating for the LED modules. The supporting structure in extruded aluminium embraces the internal surface of the diffuser, optimising the dissipation of heat and protecting service life.

The co-extruded PMMA and polycarbonate tubular housing is sealed by tightening the nut under the cable gland. With this technique, the gasket expands evenly, guaranteeing absolute sealing for any type of humidity (IP68, IP69K), even if temperatures vary significantly.

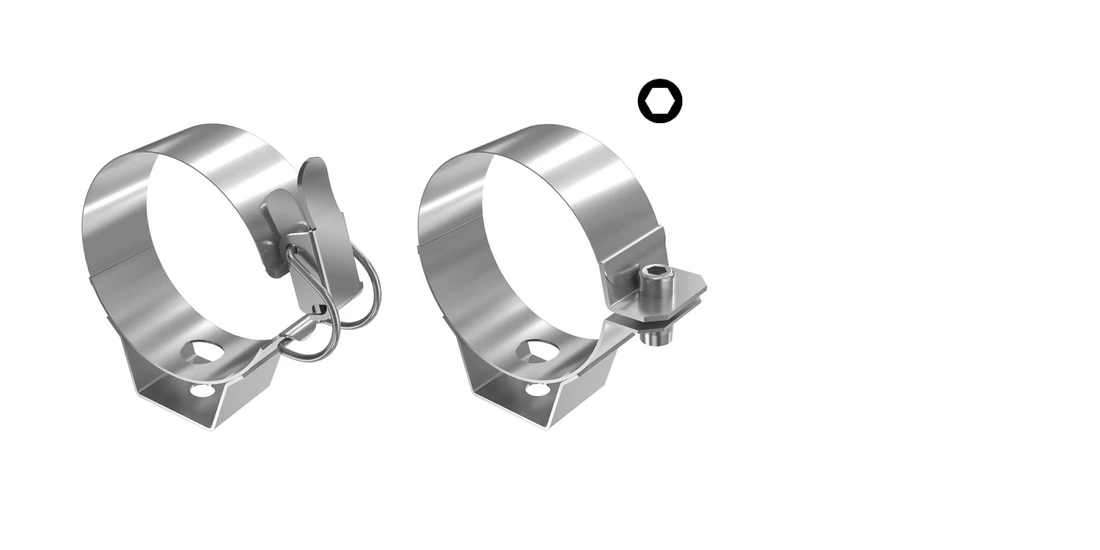

Its reinforced stainless steel end-caps and fixing straps, combined with its composite diffuser protected from corrosive substances by co-extruded PMMA, ensure exceptional resistance against the detergents used in a food environment, and the acid vapours, oils and solvents used in industry.

Equipment installed in narrow industrial spaces must be reliable and robust, which is why Sammode selected homogeneous materials with unfailing mechanical strength and no mating surfaces. The result: an ultra-durable, impact- and vibration-proof IK10 housing.

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Valid even for 24/7 use at the product’s maximum operating temperature, reflecting our unfailing commitment to our customers!

Unlike the disposable world we live in, Sammode lights are designed as modular systems. New technology can be integrated in existing fixtures: simply replace the outdated parts!

|

|

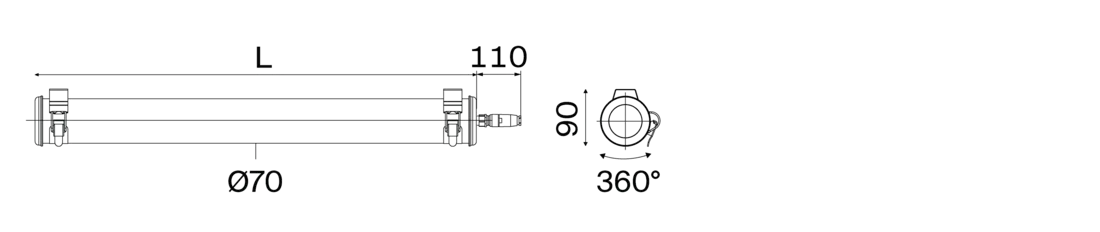

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 1650 | 675 | RAN70 12H840 POME PS3 SA | 34040020 | 13 | Data sheet | Plan | STEP DS | .TXT | Download all | 2475 | 960 | RAN70 13H840 POME PS3 SA | 34040040 | 19 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

| Reinforced fixing straps | - |

| Reinforced fixing straps with HSHC screw | BCV |

| Polycarbonate housing | PO |

| Coextruded polycarbonate/ PMMA housing with high chemical resistance | POME |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

| 3000K | 830 |

| 4000K | 840 |

| 5000K | 850 |

| Electronic gear unit for DALI dimming | RD |

| IP68 4-outlet junction box (capacity Ø7-14mm) CP00674 |

Kits for APSAD compliance

Kits for APSAD compliance

| 2 x 20 cm 304L stainless steel extensions PU44277 | |

| 2 x 5 cm 304L stainless steel extensions PU44278 |

1m HO7-RNF pre-wired high temperature cable 3G1,5²

1m HO7-RNF pre-wired high temperature cable 3G1,5²

| Stripped free end CAB0076 | |

| Wieland® plug IP68/IP69K (capacity : Ø10-14mm) CAB0140 | |

| Wieland® plug and Y spliter for loop-in/out CAB0146 |

| Light source |

|

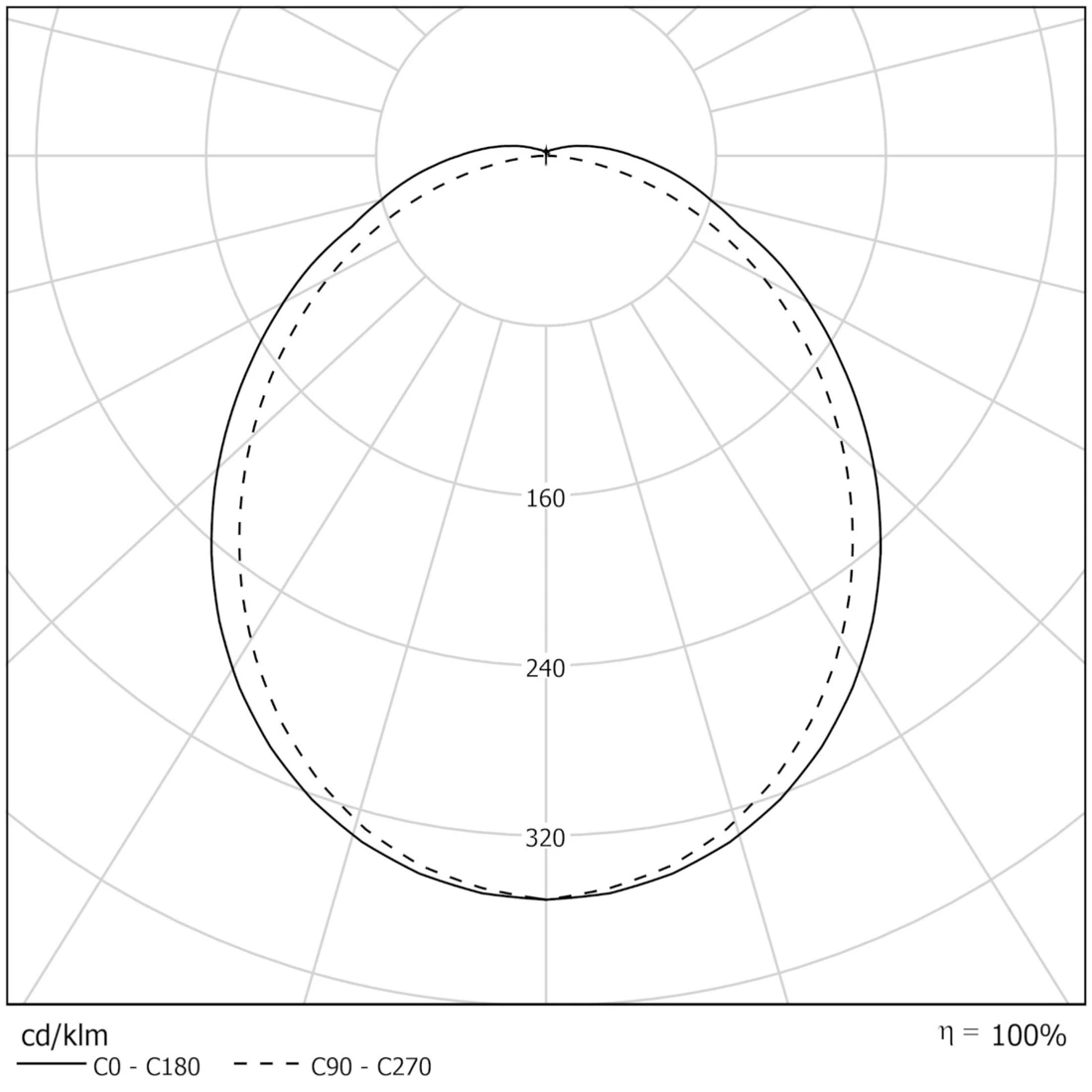

| Optics |

|

| Lighting comfort |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Gaskets |

|

| Method of construction |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|