Jamin

Tube ø100 and 133 for industrial ATEX zone 2, 21, 22 atmospheres

The ideal combination of safety and functionality for lighting ATEX gas zones

Explosive gas environments, zone 1; II 2G Ex eb mb IIC T6 Gb (Zones 1&2) - II 2D Ex tb IIIC T80°C Db IP66 (Zones 21&22) markings

The ALDER luminaire benefits from an 8-year warranty in intensive operating conditions and is qualified for the worst possible substances thanks to its T6 classification. This model is primarily designed to make your life easier. This model is incredibly light and easy to install thanks to the sliding gear tray, and is also fitted with an impact-proof composite diffuser, able to withstand chemical damage and UVs. No need to choose between safety or convenience, Sammode offers you all this in one, with the ALDER.

Corrosive substances, acid vapours

Oils & hydrocarbons

UV radiation and bad weather

Dust and humidity

Washing with a high-pressure jet

Health and safety requirements according to IFS, BRC and HACCP texts

Permanent use at temperatures of up to 40°C

Repeated turning on and off

Heavy mechanical impacts

Sammode has succeeded two feats with its high-performance LED components in a sealed housing with optimal thermal properties and weight: strong flux providing better lighting with less light points, and a lower surface temperature, classed T6, designed by Graal architecture for use in gas zones! Results: an ultra-versatile and much lighter luminaire versus the competition, with no compromises on safety.

External 100% stainless steel parts, combined with a composite diffuser in co-extruded polycarbonate-PMMA, offering exceptional resistance to hydrocarbons, solvents, the detergents used in the food industry, IK10 mechanical impacts and UV radiation.

Quick and easy connections thanks to a smart sliding gear tray (patented SLIDE© system). Just one of the benefits of this approach? Electrical connections can be plugged directly into the lights on our models with 2 cable glands, so there is no need to use ATEX junction boxes.

Sammode has everything covered! Versions with 2 cable glands, including 1 blanked off, and connection to the removable internal gear tray possible. Or a pre-cabled version with a pluggable Atex lead, cutting down on site time with no risk of losing parts.

Ultimate IP68 and IP69K sealing! Thanks to its 3-seal system and uniform tightening with a central screw, the housing remains firmly sealed to prevent humidity or fine dust from entering and to withstand high-pressure washing. Guaranteed health and safety, everywhere and well into the future!

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Product with Atex certification for gas zones 1 & 2 and dust zones 21 & 22, issued by an independent laboratory. Our warranty is valid even for 24/7 use at the product’s maximum operating temperature.

Unlike the disposable world we live in, Sammode lights are designed as modular systems. New technology can be integrated in existing fixtures: simply replace the outdated parts!

|

|

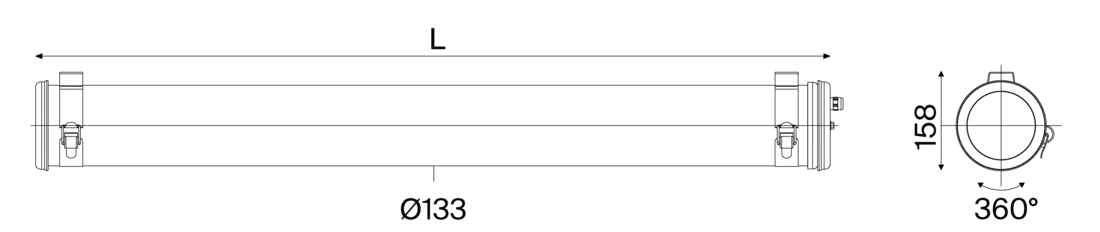

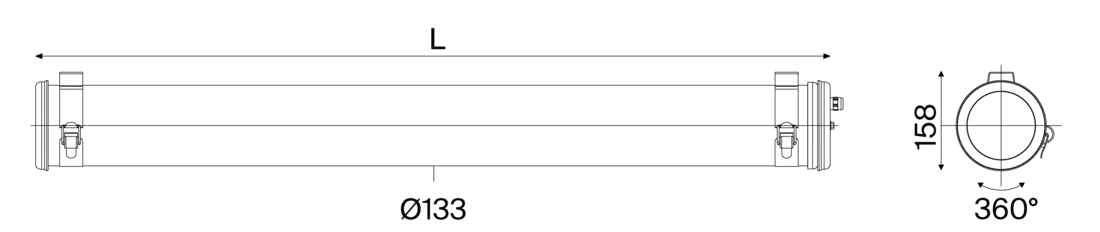

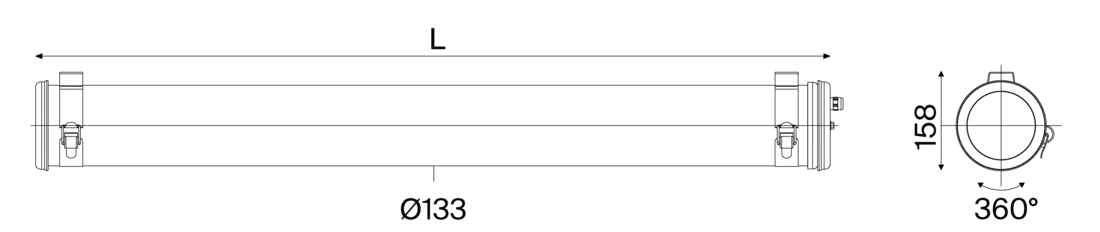

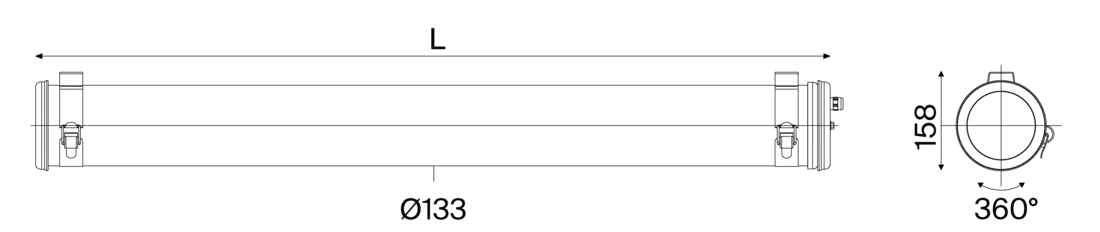

| Ø (mm) | Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 2000 | 685 | ALD133 700 2000-840 POME 213 BRS | 19905202 | 21 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 3100 | 685 | ALD133 700 3100-840 POME 213 BRS | 19905206 | 28 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 4100 | 1295 | ALD133 1300 4100-840 POME 213 BRS | 19905210 | 35 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 6200 | 1295 | ALD133 1300 6200-840 POME 213 BRS | 19905214 | 52 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 5100 | 1595 | ALD133 1600 5100-840 POME 213 BRS | 19905218 | 41 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 7700 | 1595 | ALD133 1600 7700-840 POME 213 BRS | 19905222 | 65 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

|

|

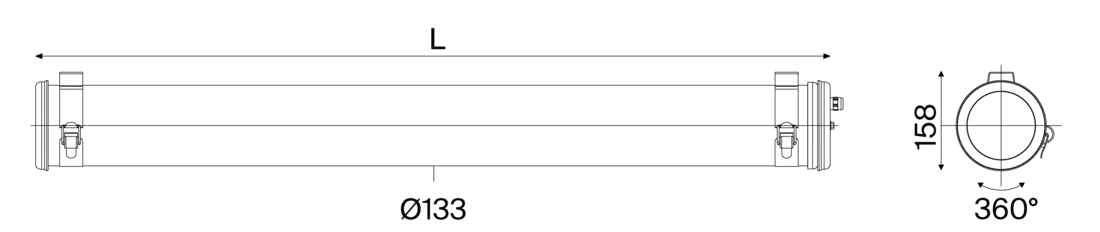

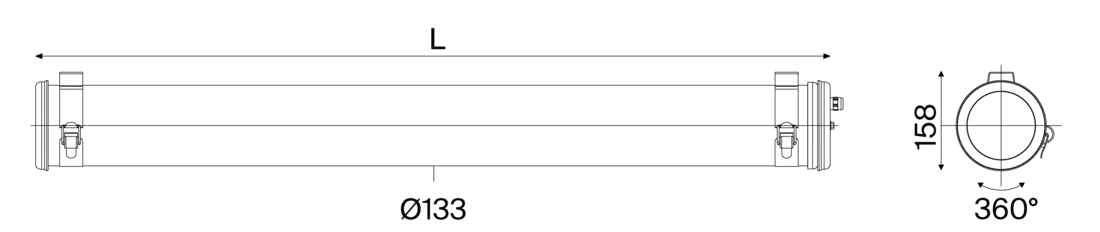

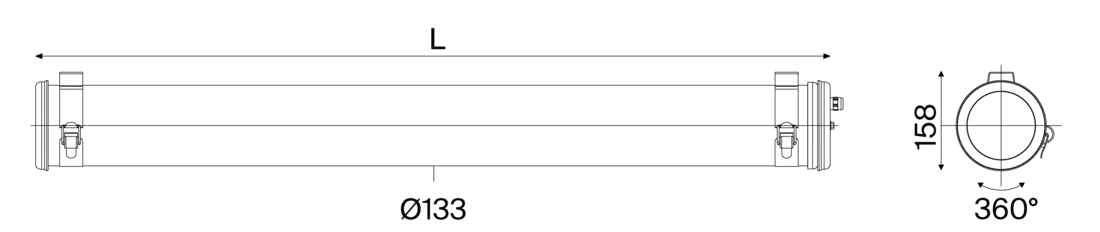

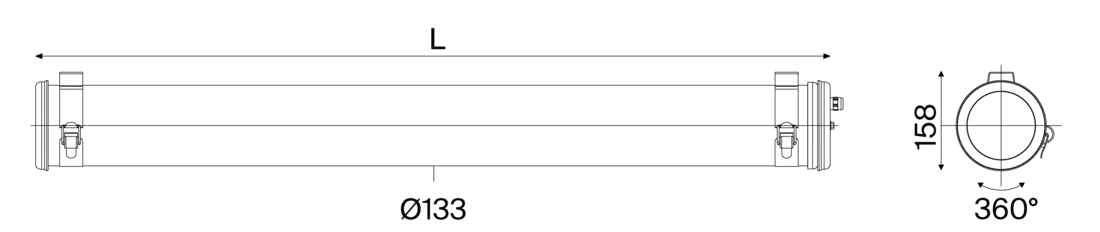

| Ø (mm) | Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 2000 | 685 | ALD133 700 2000-840 POME 113 BRS | 19905200 | 21 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 3100 | 685 | ALD133 700 3100-840 POME 113 BRS | 19905204 | 28 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 4100 | 1295 | ALD133 1300 4100-840 POME 113 BRS | 19905208 | 35 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 6200 | 1295 | ALD133 1300 6200-840 POME 113 BRS | 19905212 | 52 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 5100 | 1595 | ALD133 1600 5100-840 POME 113 BRS | 19905216 | 41 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 7700 | 1595 | ALD133 1600 7700-840 POME 113 BRS | 19905220 | 65 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

|

|

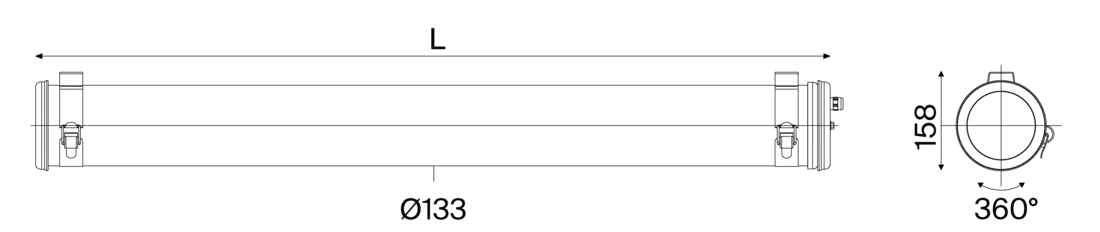

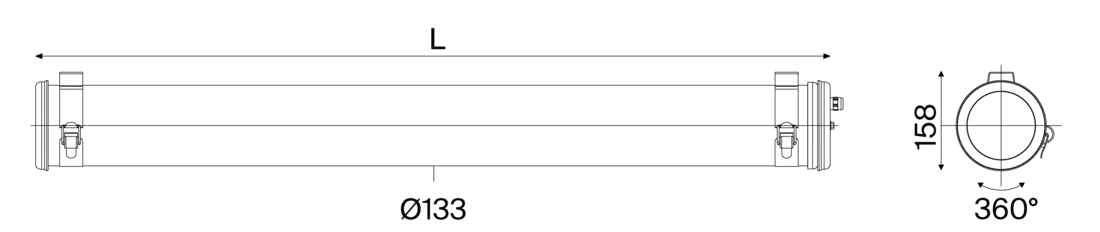

| Cord length (m) | Designation | Code | Data sheet | Plan | STEP DS | .TXT | Download all | 0,1 | CABL HO7RNF-BK ATEX-PLUG 0.1M 3G1.5 | CAB0141 | Data sheet | Plan | STEP DS | .TXT | Download all | 1 | CABL HO7RNF-BK ATEX-PLUG 1M 3G1.5 | CAB0130 | Data sheet | Plan | STEP DS | .TXT | Download all | 3 | CABL HO7RNF-BK ATEX-PLUG 3M 3G1.5 | CAB0143 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

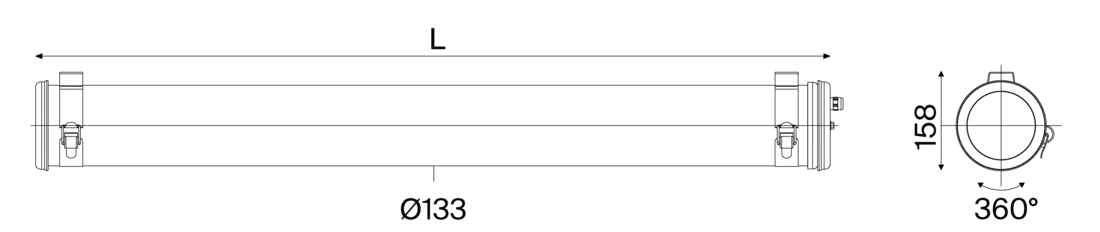

| Polyamide capacity Ø8-13 mm | 113 |

| Polyamide capacity Ø10-15 mm | 116 |

| Nickel-coated brass capacity Ø5-14 mm | 113LN |

| Polyamide capacity Ø8-13 mm | 213 |

| Polyamide capacity Ø10-15 mm | 216 |

| Nickel-coated brass capacity Ø5-14 mm | 213LN |

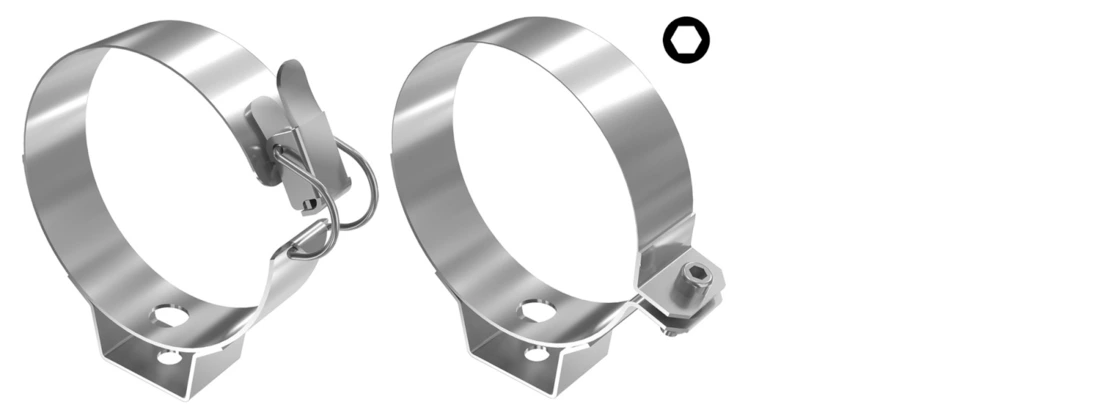

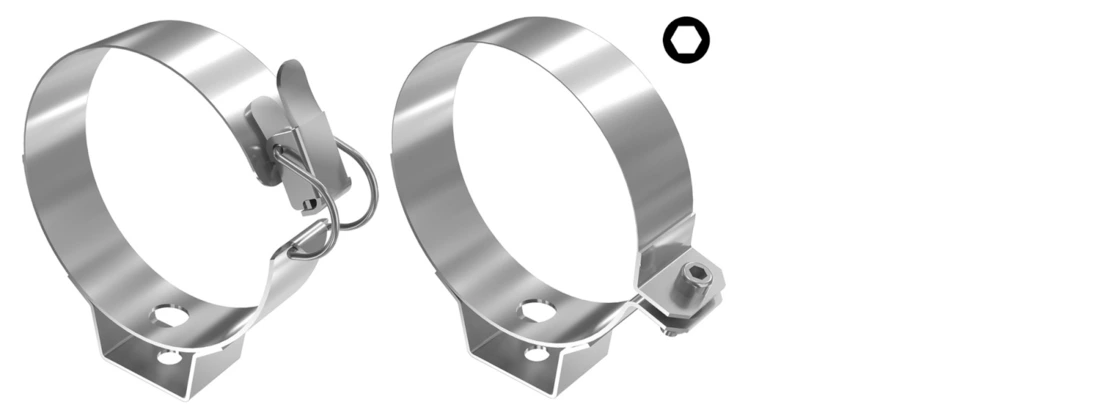

| Reinforced fixing straps | BRS |

| Reinforced fixing straps with HSHC screw | BRV |

| Polycarbonate housing | PO |

| Coextruded polycarbonate/ PMMA housing with high chemical resistance | POME |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

| 4000K | 840 |

| 5700K | 857 |

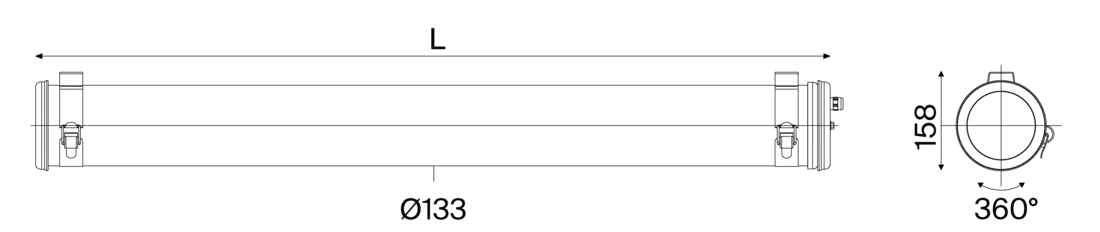

| 1 fixing strap ø133 CP00949 |

| Length 800mm PU6362 | |

| Length 1400mm PU6286 | |

| Length 1700mm PU6363 |

| Adapter ø1"1/4 (=42mm) PU4321 | |

| Adapter ø1"1/2 (=49mm) PU4083 | |

| Adapter ø2" (=60mm) PU4082 |

| Light source |

|

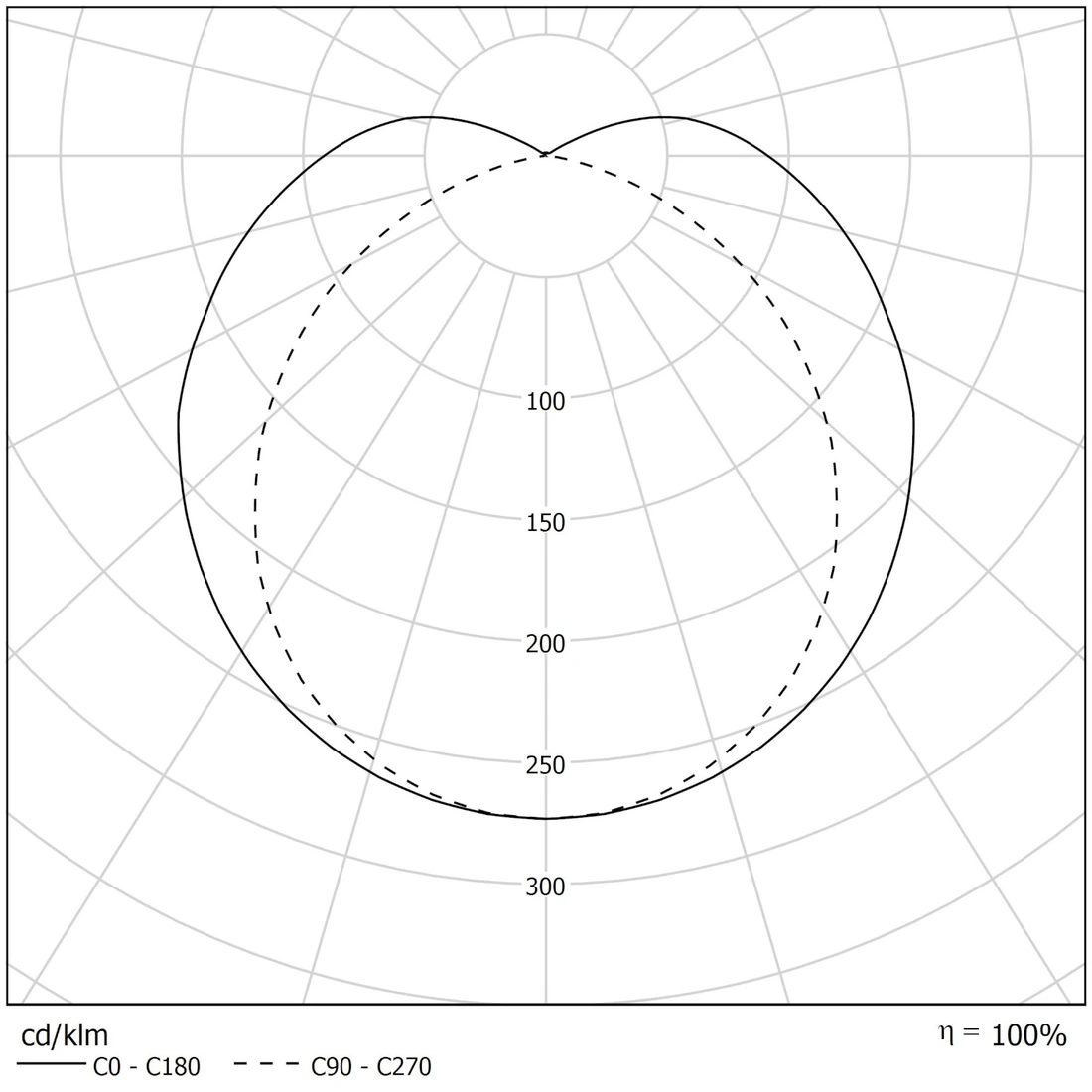

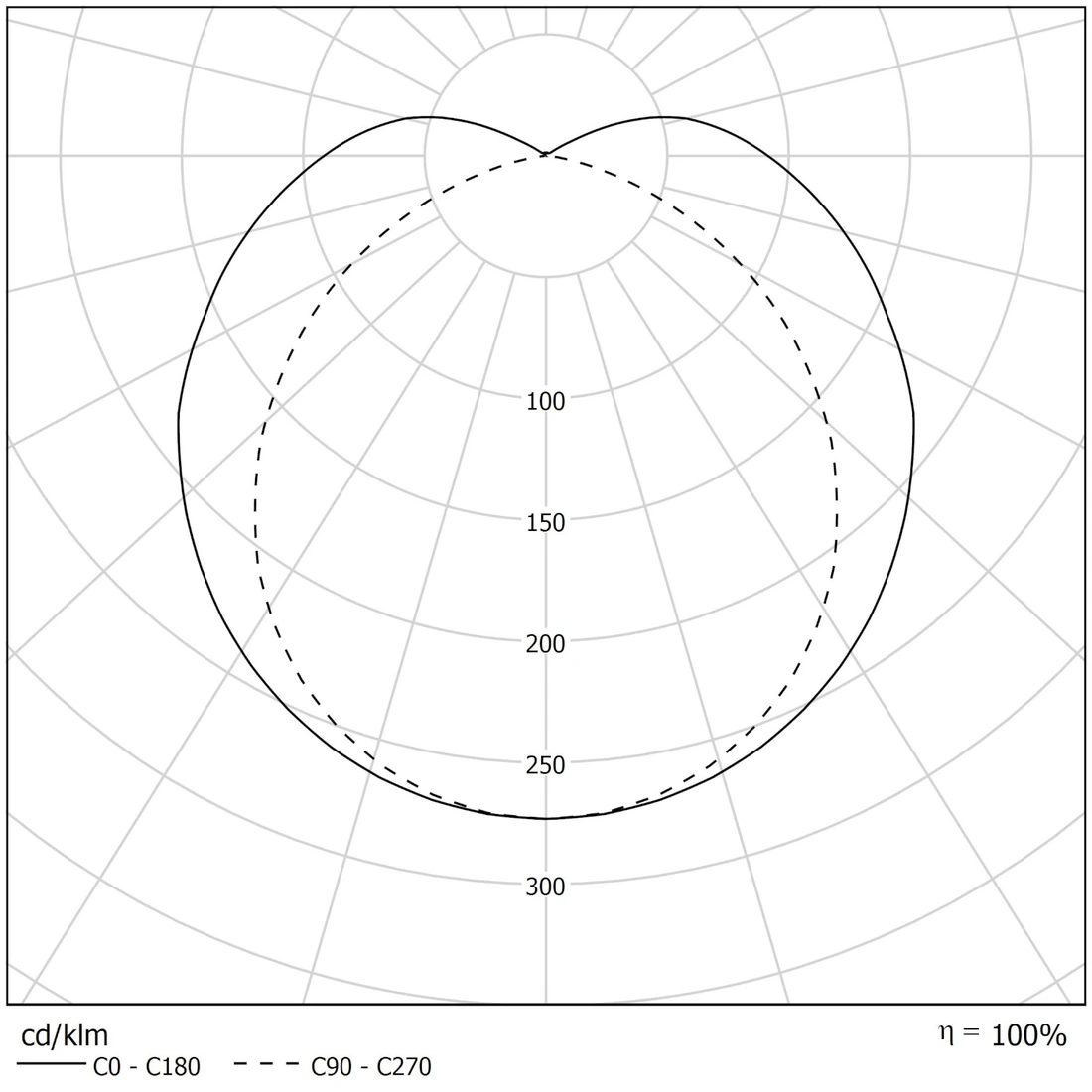

| Optics |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Operating temperature |

|

| Electrical class |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Gaskets |

|

| Method of construction |

|

| ATEX / IECEx |

|

| Marking |

|

| Temperature class |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|