Lighting for high-temperature processes, ATEX zones and workshops

The paper industry is one of the toughest environments for lighting. Luminaires must be able to survive in places operators would rather get out.

From roller presses to dryers and final processing, Sammode lighting solutions are designed to provide long-term lighting in the hottest and dampest environments and to withstand vibrations and chemical attacks. In addition, the electronics and LED modules fitted in Sammode luminaires are designed to resist electrical disturbance, voltage surges and significant temperature variations. This approach guarantees an optimal service life for luminaires and a substantial reduction in maintenance costs.

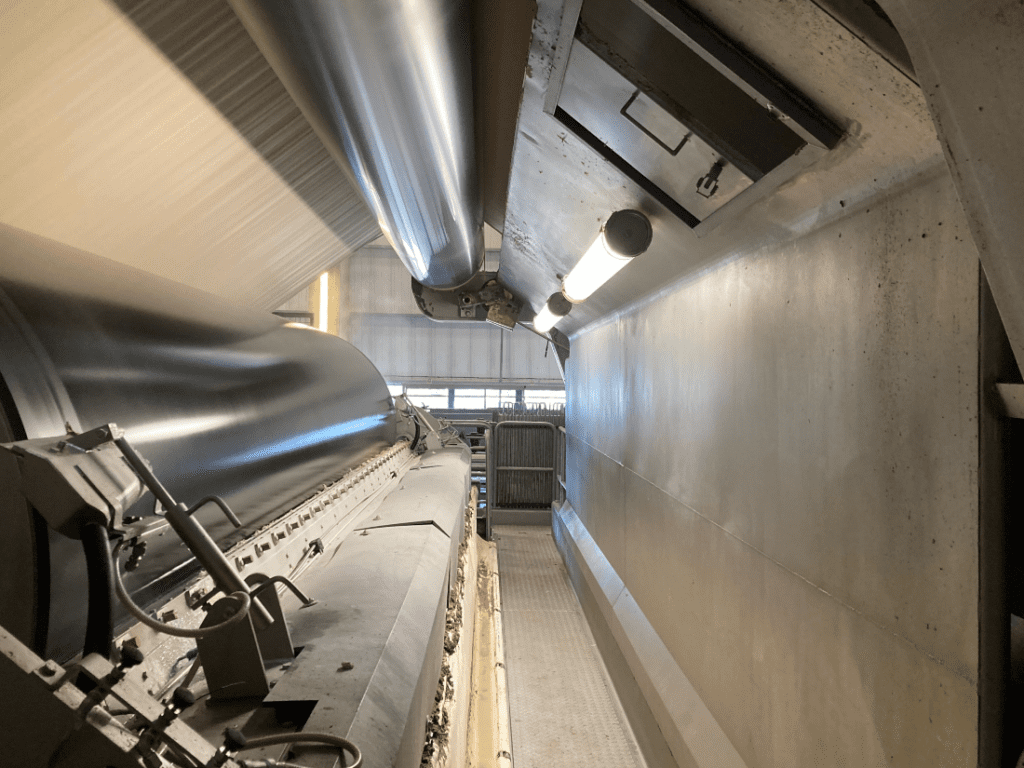

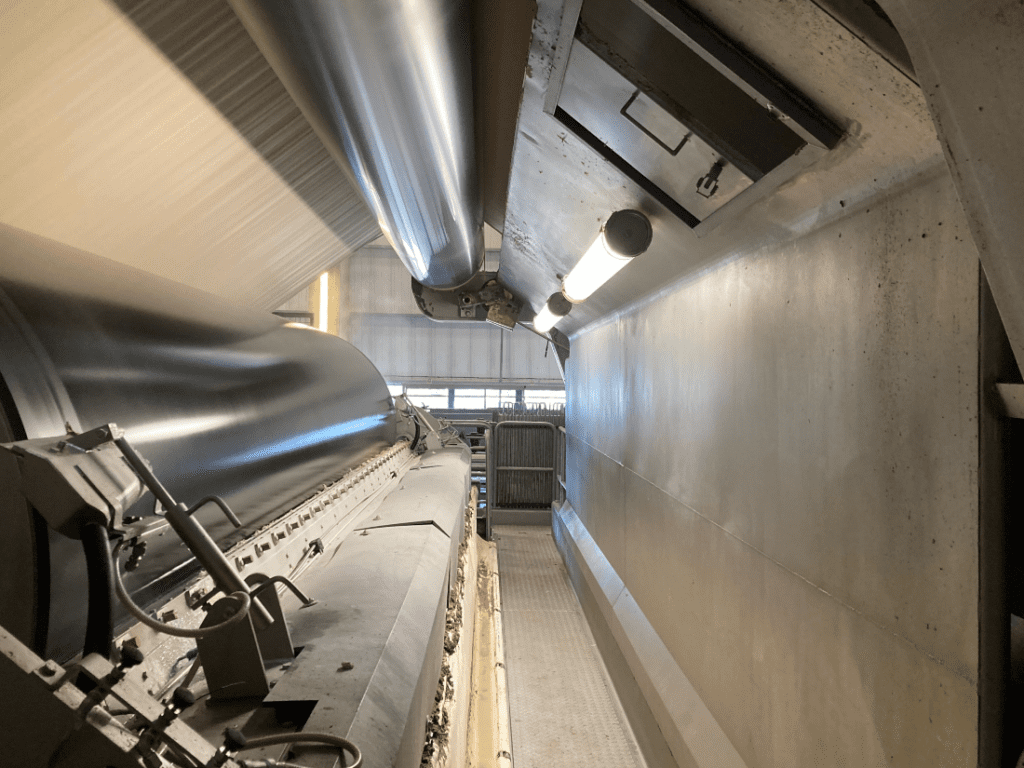

When it leaves the formation table, the sheet is hot rolled between cylinders coated with an absorbent felt. The press room is hot and damp with vibrations caused by the machinery.

We recommend the JOULE X-Heat luminaire for lighting near to the paper press. Thanks to the sealed, vibration-resistant housing and to the embedded LED technology able to withstand high temperatures of up to 70°C, this luminaire is ideal for paper press areas. The JOULE X-Heat is also equipped with reinforced industrial electronics, designed to withstand electrical disturbance, voltage surges and significant temperature variations.

Requirements

- Extensive humidity

- High temperatures

- Intense and constant vibrations

Recommended products

-

Joule X-Heat

High temperature ø133 tube light for extreme industrial atmospheres

After pressing, the sheet is smoothed and dried against steam-heated cast iron drums. The sheet is then coated or finished. After finishing, the paper is rolled into reels. Temperatures are extremely high for most of these stages, humidity is also high due to the steam and chemical hazards must be considered. Machines also produce strong vibrations.

With their completely sealed, corrosion-proof housing able to withstand vibrations, JOULE X-Heat and LESLIE X-Heat tubular luminaires (model with a borosilicate glass diffuser) are fully compatible with the conditions found at paper mills; they can be backed up by the PAULI HT200 X-Heat, specifically designed for the most extreme temperatures.

Requirements

- Extensive humidity

- Extreme temperatures

- Intense vibrations

- Chemical attacks

Recommended products

-

Joule X-Heat

High temperature ø133 tube light for extreme industrial atmospheres

-

Leslie X-Heat

High temperature borosilicate glass tube ø133 for highly corrosive atmospheres

-

Pauli HT200 X-Heat

Very high temperature ø133 incandescent tube light

The quality of the paper depends on the targeted use of chemicals and additives. Hydrogen peroxide, alkaline or acidic products and other additives are stored in stainless steel tanks or plastic tanks reinforced with fibre glass. These chemical storage spaces are sensitive sites where lighting solutions must be compatible with a highly explosive atmosphere and chemical attacks.

Thanks to their borosilicate glass or co-extruded PMMA diffusers, SABATIER Xtrem and BOYLE Xtrem luminaires can withstand this type of extreme environment over the long-term. By design, the materials used ensure unfailing abrasion resistance and can withstand any type of chemical attack. These LED luminaires are ATEX/IECEx certified and are designed to provide 100% safe and durable lighting in ATEX zone 1 (SABATIER Xtrem) and ATEX zone 2 (BOYLE Xtrem) environments.

Requirements

- Explosive atmosphere (ATEX Zone 1/ATEX Zone 2, 21-22)

- Chemical attacks

Recommended products

-

Boyle Xtrem

Borosilicate glass tube ø100 and ø133 for extreme or highly corrosive ATEX zone 2, 21 and 22 atmospheres

-

Sabatier Xtrem

Borosilicate glass tube ø133 for extreme or highly corrosive ATEX zone 1 atmosphere

Some areas of the paper production workshops are particularly damp and both machines and luminaires must withstand corrosion and strong chemical attacks. Temperatures in these areas are also high and can reach 50°C at the ceiling.

Sammode recommends the use of the CUGNOT Xtrem LED tubular luminaire to manage the specific conditions prevailing in these damp zones. The design of the housing and the robust materials used (stainless steel and composite diffuser) mean that this model is totally sealed and durably resistant before corrosive vapours and high temperatures.

Requirements

- High temperatures

- Humid atmosphere

- Corrosion

Recommended products

-

Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

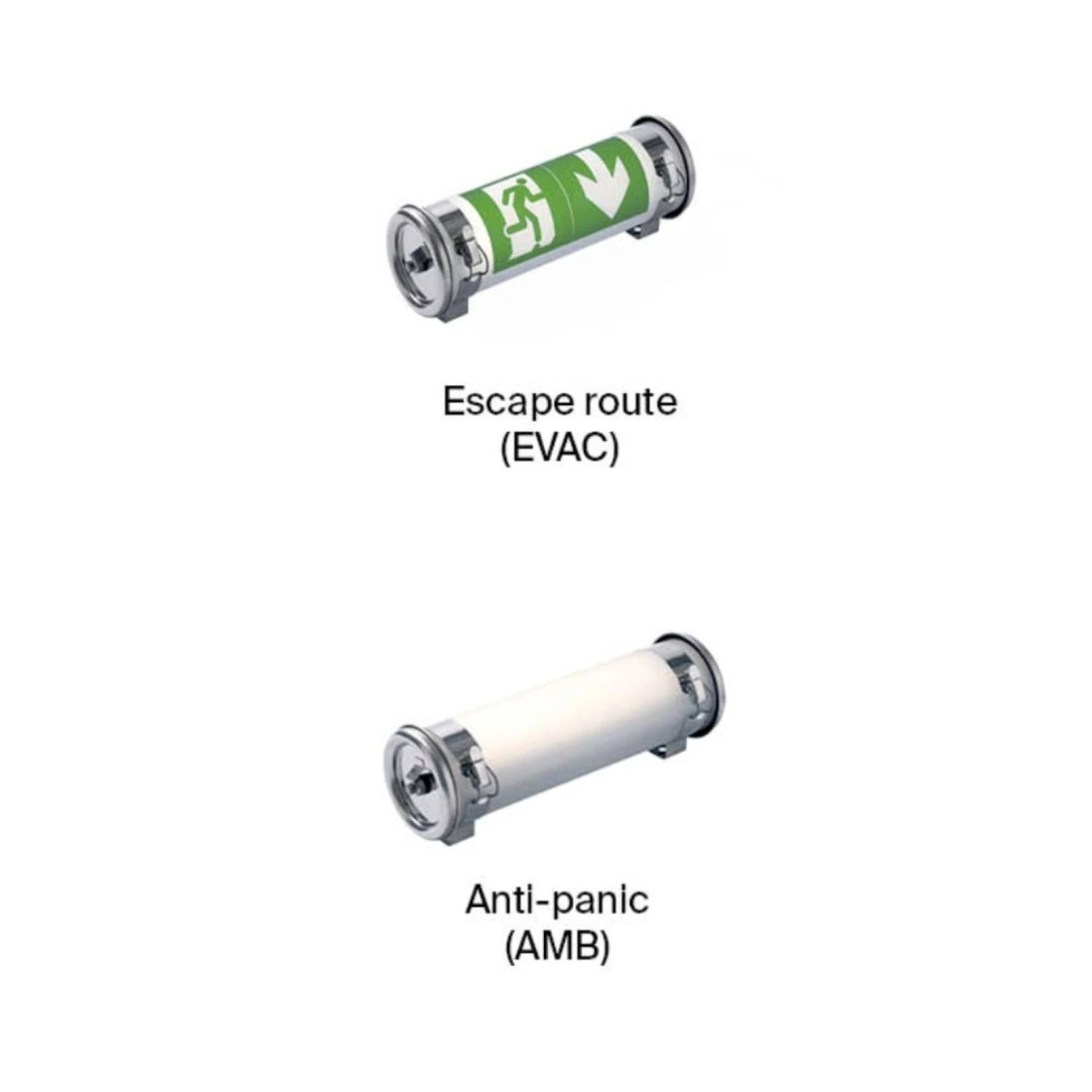

In a paper mill where people and machines interact on a daily basis, the installation of emergency lighting solutions is a legal and safety requirement. Standalone emergency luminaires, luminaires for centralised sources (LSC) or replacement lighting all provide around-the-clock visibility throughout the paper mill, in production areas, corridors and at emergency exits if the main power grid fails.

Sammode has developed emergency lighting solutions that offer the same guarantees and resistance as its other industrial luminaires. These luminaires are equipped with batteries or a connection to a secondary emergency power source (LSC), guaranteeing evacuation (EVAC) or ambient (AMB) lighting if the main power grid fails.

Requirements

- Powered by a separate source to the main power grid

- Adapted to the environmental conditions in the zone

- Compliant with EN 60 598-2-22 and NF AEAS certified (France)

Recommended products

Une conception adaptée aux environnements extrêmes.

Résistance aux fortes températures

Matériaux résistants jusqu’à +200°C Résistance aux dilatations thermiques

ATEX / IECEx

Luminaires adaptés aux Zones ATEX 1, 2, 21-22

IP68-69K

Etanchéité parfaite face à l’humidité Absence d’empoussièrement interne

Sammode expertise

Diagnosis and recommendations

We start by analysing your operating conditions, installation requirements and other specific needs, and then recommend the most suitable solutions.

Lighting studies

Our lighting studies are designed to identify the precise quantity of luminaires and quality of the lighting solution required, while minimsing the number of light sources and energy use.

Control systems

To reduce your energy bill and improve your lighting control, our experts will suggest the management solutions best suited to your situation.

Developing special products

As both designer and manufacturer, we systematically study the best technical solutions and are able to adapt them to meet your needs.

On-site testing and support

We can manage your project from start to finish, from studies to installation, including any tests required in actual operating conditions.

Ultimate 8-year warranty

We offer an ultimate 8-year warranty for most of our products, the only such offer available on the lighting market under intensive 24/7 operating conditions.