Bering X-Cold

ø100 & 133 tube light for very low temperature industrial environments

The most efficient Extreme Cold solution to light up high shelving

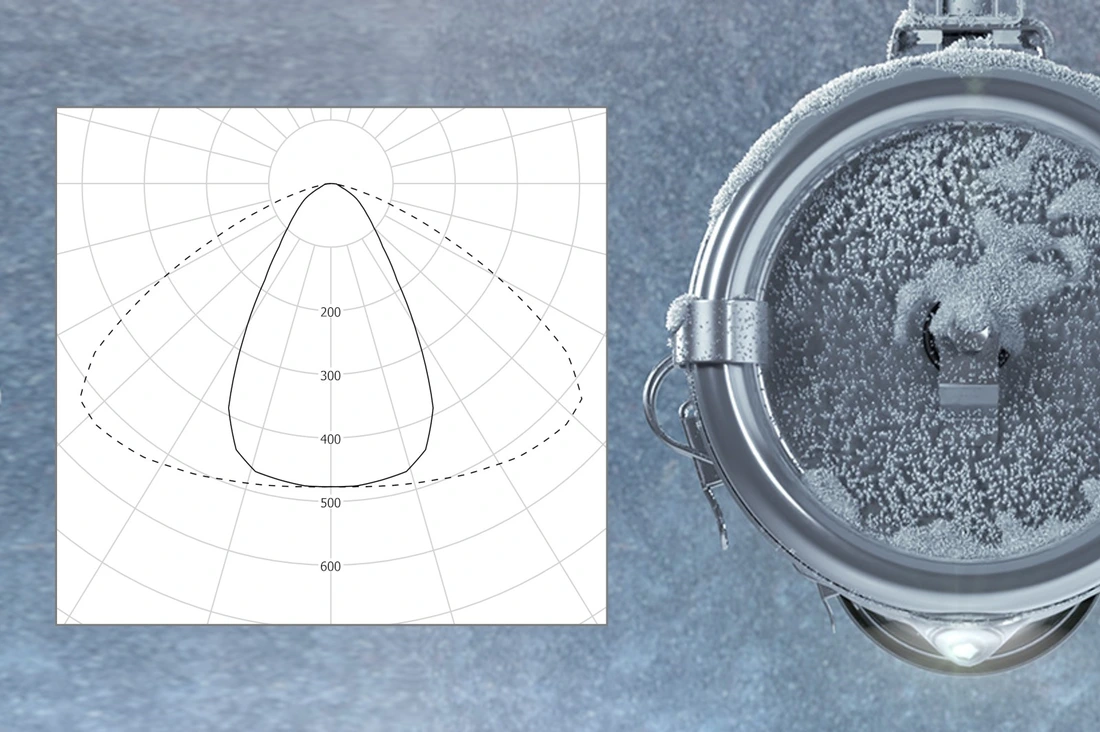

Cold rooms with high shelving require reliable lighting and optimal light distribution. The Barents luminaire is specifically equipped with a highly efficient high-intensity LED source and offers the optical performance of a floodlight with the legendary sealing of a Sammode tubular luminaire.

Corrosive substances, acid vapours

UV radiation and bad weather

Dust and humidity

Freezing temperatures, frost

Washing with a high-pressure jet

Health and safety requirements according to IFS, BRC and HACCP texts

Permanent use at temperatures of up to -40°C

Extreme variation in temperature

Thermal shocks

Repeated turning on and off

Heavy mechanical impacts

Voltage surges up to 4 kV, power surges

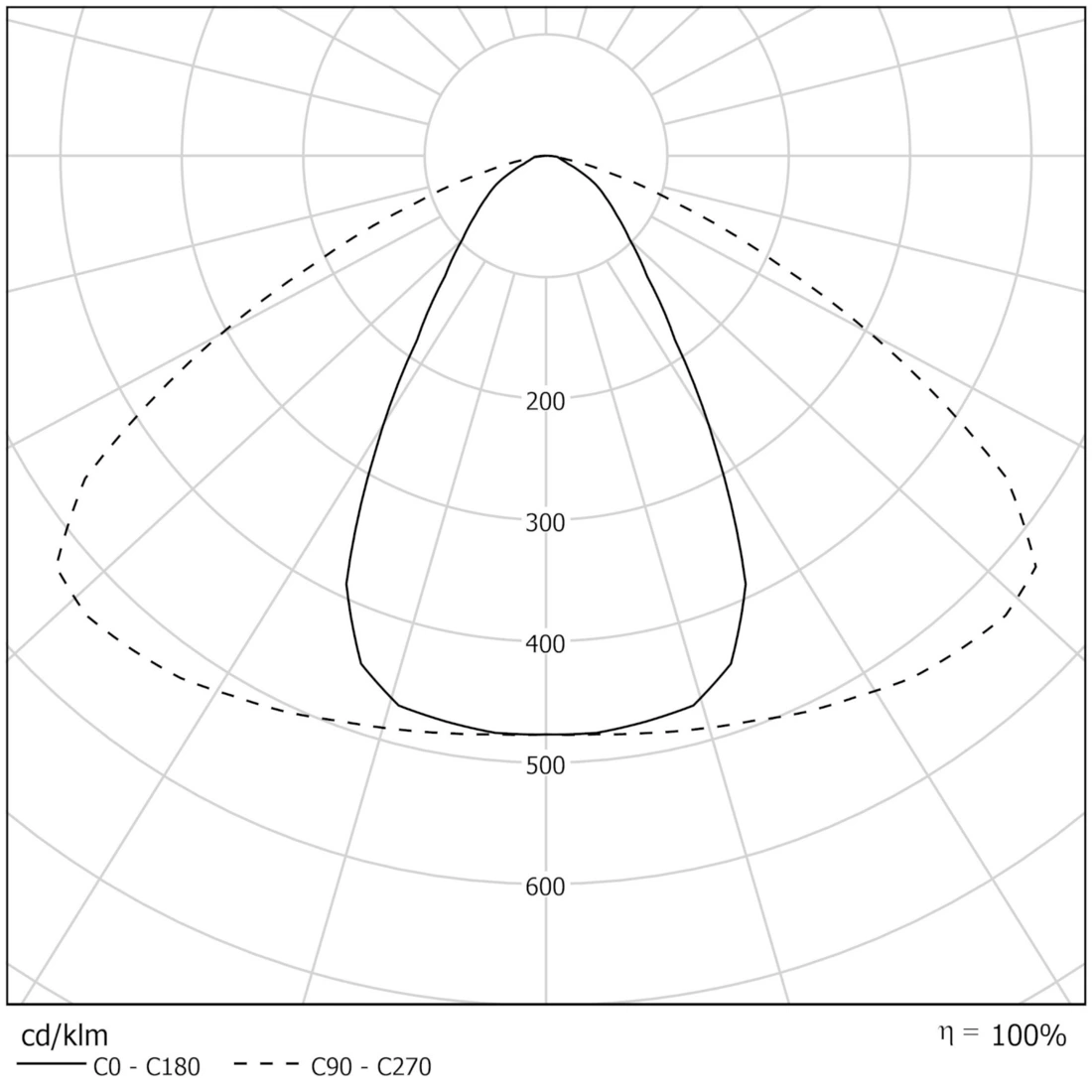

Optimised lighting in large storage areas with high ceilings requires strong luminance and lights designed for intensive use. So what’s the secret? High-performance LED modules combined with an elliptical beam linear lens, providing durable, low-energy lighting right where you need it.

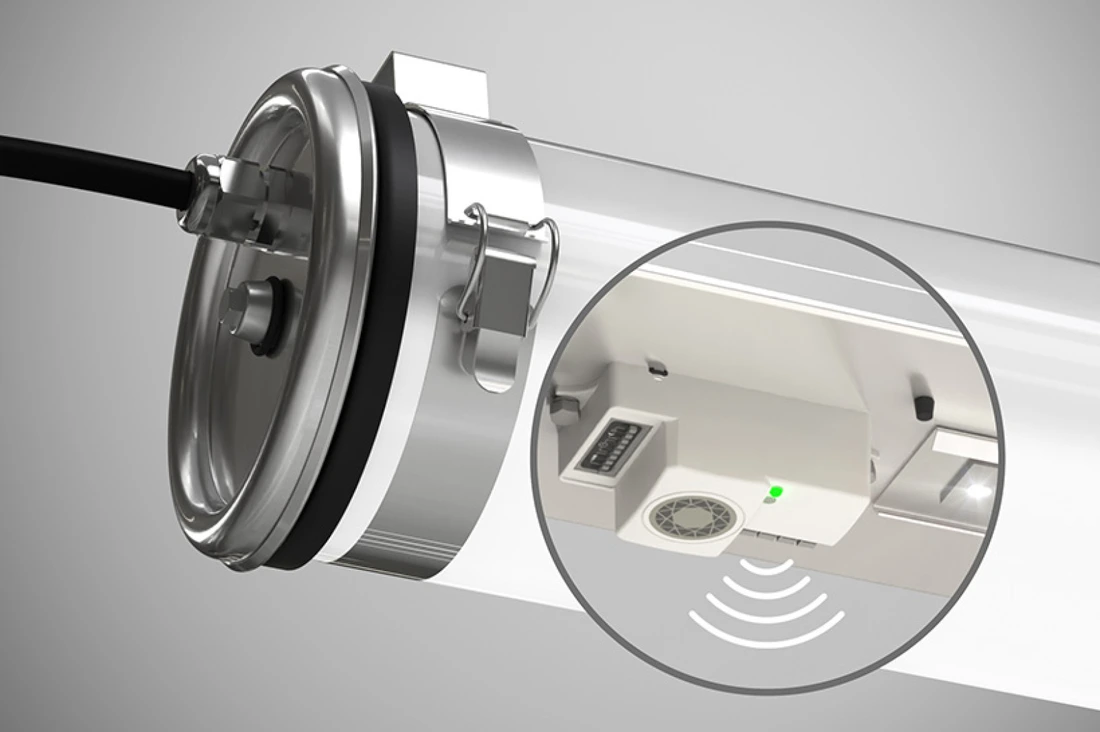

Forget those heavy, unwieldy cast aluminium spotlights: Sammode has come up with a new and more affordable alternative offering nothing but benefits: a powerful, efficient and reliable LED driver in an ultra-light well-sealed tubular Plug & Play housing able to withstand thermal shocks. Who could ask for more?

This luminaire, with its silicone gaskets, composite diffuser and stainless steel end-caps and fixing straps, meets regulations on food grade products. The sealed housing, with its axial tightening (Screw© system), eliminates any risk of broken or lost parts, and helps to ensure compliance with IFS, BRC and HACCP requirements for food sites.

Sammode opted for a composite diffuser, combining the mechanical solidity (IK10) of polycarbonate with the chemical resistance of a thin layer of co-extruded and indissociable PMMA. This approach provides ideal protection from the detergents used for site cleaning or maintenance phases.

Only light areas when you need to, thanks to the optional motion sensor, based on a high-resistance sensor. When combined with the switch-off warning function, these models cut your energy bills by up to 90% in less-frequented areas, while maintaining the safety you need.

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Valid even for 24/7 use at the maximum operating temperature for the product. 8-year warranty you will not find anywhere else on the market, reflecting our unfailing commitment to our customers!

Even after 15 or 20 years’ use, every single part we supply can be easily replaced, with no need to send it back to us. No one else offers a guarantee of lifelong lighting solutions!

|

|

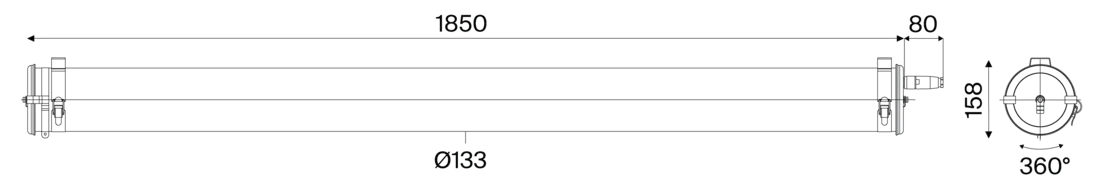

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 13700 | 1850 | BAR133 16H840 POME PS3 BRS | 32100020 | 115 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

| Polyamide capacity Ø5-12mm | 113 |

| Polyamide capacity Ø7-14mm | 116 |

| Nickel-coated brass capacity Ø5-14 mm | 113LN |

| IP68/69K quick-lock plug with threaded ring (capacity: Ø8 to 10 mm) | PS3 |

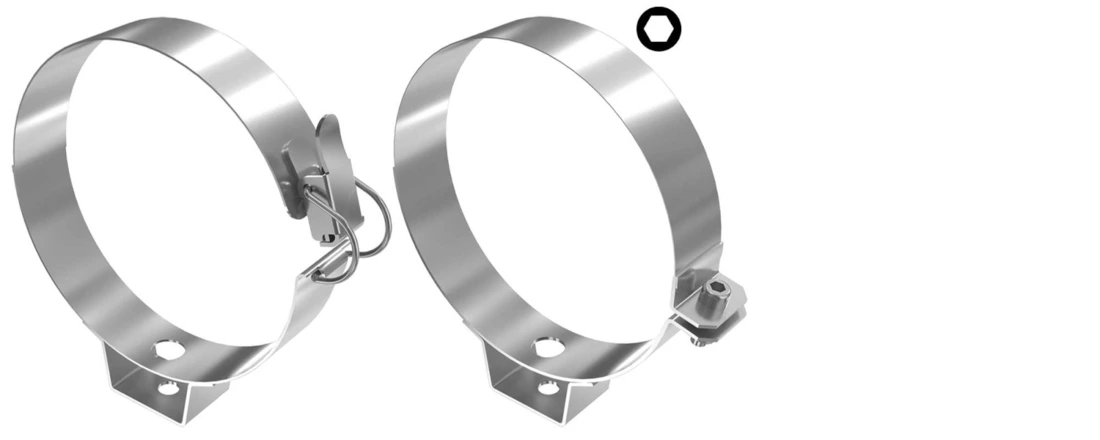

| Reinforced fixing straps | BRS |

| Reinforced fixing straps with HSHC screw | BRV |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

| 3000K | 830 |

| 4000K | 840 |

| 5000K | 850 |

| Electronic gear unit for DALI dimming | RD |

| Switch-off warning function (for sensor/timer) | RC |

| Built-in presence sensor for high bay (length increased by 85mm) | SIHB |

| IP68 4-outlet junction box (capacity Ø7-14mm) CP00674 |

Kits for APSAD compliance

Kits for APSAD compliance

| 2 x 20 cm 304L stainless steel extensions PU44277 | |

| 2 x 5 cm 304L stainless steel extensions PU44278 |

1m HO7-RNF pre-wired cable 3G1,5²

1m HO7-RNF pre-wired cable 3G1,5²

| Stripped free end CAB0080 | |

| Wieland® plug IP68/IP69K (capacity : Ø10-14mm) CAB0095 | |

| Wieland® plug and Y spliter for loop-in/out CAB0145 |

| Light source |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Optics |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Gaskets |

|

| Method of construction |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|