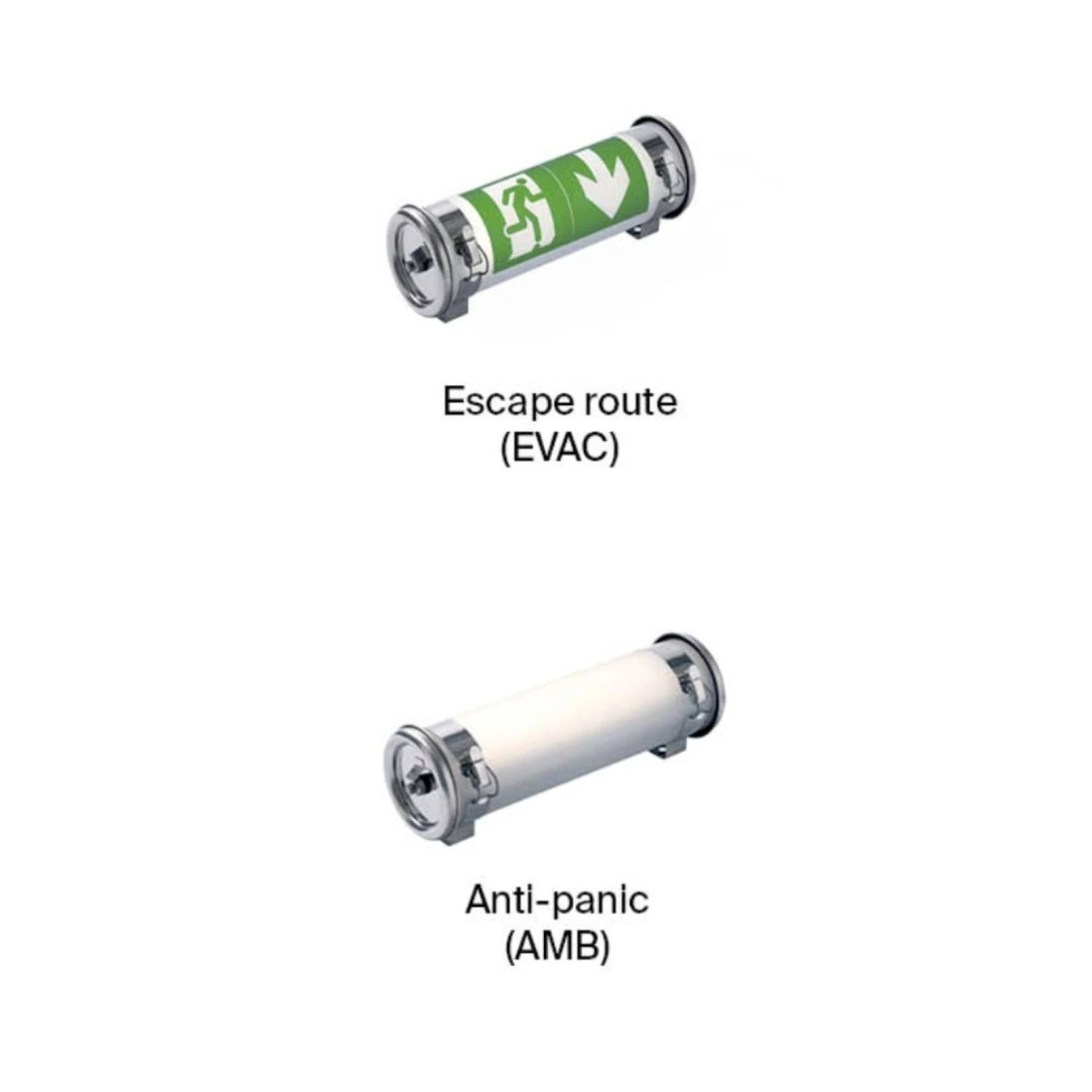

Projectors on Ship/Shore Crane

The power of our floodlights can be adjusted according to the installation height of the floodlight and the lighting requirements. It is also possible to configure the floodlight to produce an asymmetrical beam and concentrate the light on a defined area.