Pascal

Tube ø100 and 133 for industrial atmospheres

The ideal solution for clean rooms with crawlspace ceiling

Applications requiring high levels of health and safety: cleanrooms as per ISO 14644-1

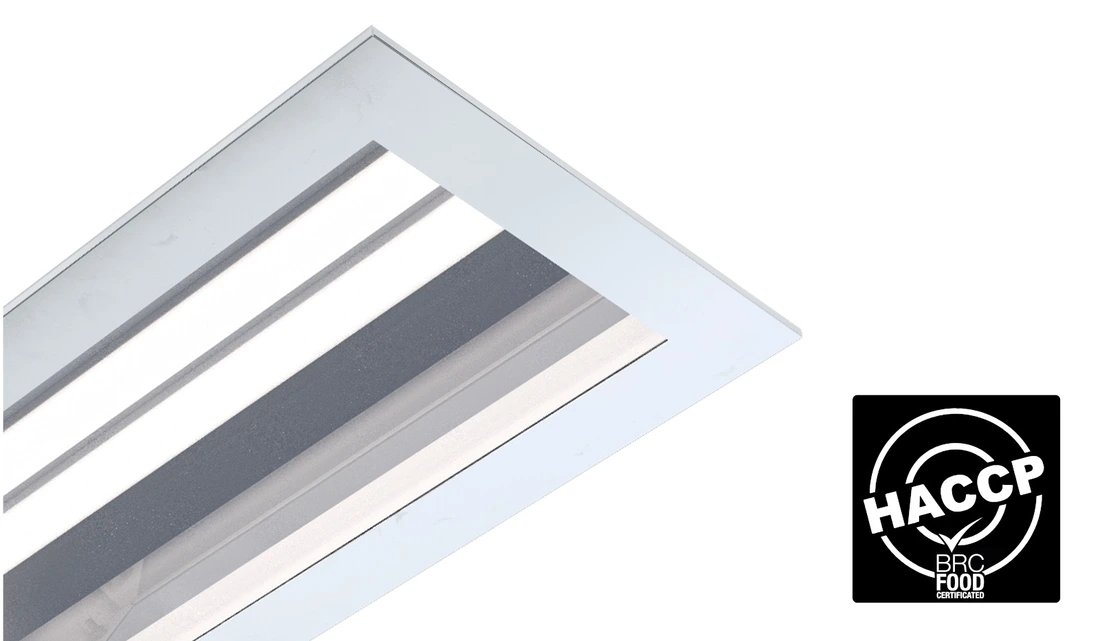

The Calmette is an original top-opening embedded LED and ideal for lighting in zones with controlled atmospheres. This well-sealed luminaire is ideal for food environments where health and safety are critical thanks to its materials with excellent mechanical and chemical resistance.

Corrosive substances, acid vapours

All types of humidity

Washing with a high-pressure jet

Health and safety requirements according to IFS, BRC and HACCP texts

Permanent use at temperatures of up to 40°C

Extreme variation in temperature

Repeated turning on and off

Mechanical impacts

Voltage surges up to 4 kV, power surges

The CALMETTE is ideal in sterile zones and easy to disinfect thanks to a smooth front panel. It can also be embedded from below in the load-bearing ceiling. The luminaire is sealed by adding a bead of silicone between the front panel frame and the ceiling, and securing with 2 screw-on brackets with threaded rods on the back.

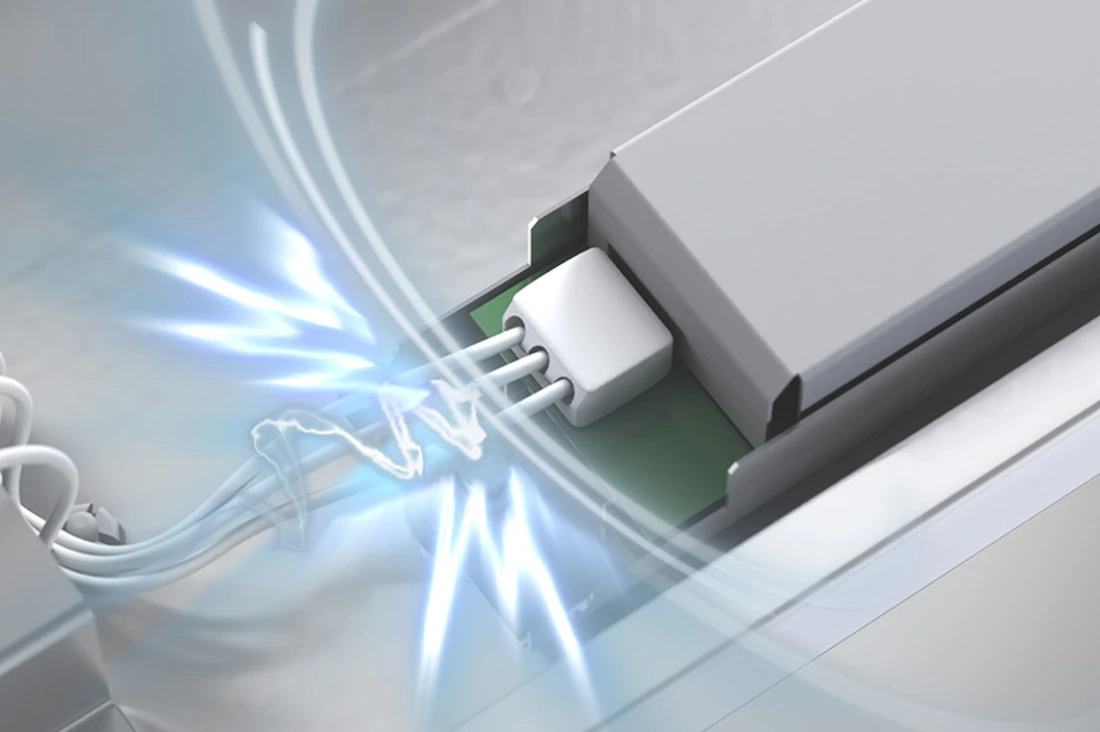

The CALMETTE is fitted with a 2-part casing (Clean© system). The lower casing is closed with a PMMA cover able to withstand detergents and containing high-performance aluminium reflectors. The removable top cover with 2 handles contains the LED driver and sources. Maintenance can be carried out safely outside of the production zone.

Extremely aggressive detergents are required on a daily basis to ensure high sanitary levels in clean rooms. Thanks to its PMMA cover with a stainless steel frame, the CALMETTE is unaffected by corrosion, and meets food safety regulations helping to ensure compliance with IFS, BRC and HACCP requirements for food sites.

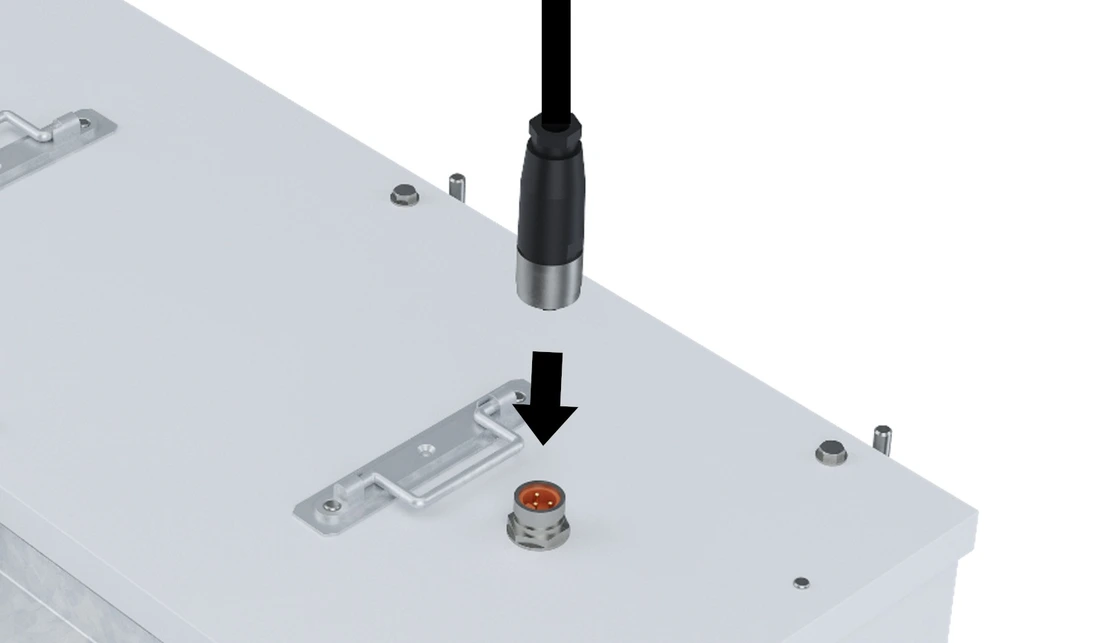

Installation in record time and risk-free operations above the load-bearing ceiling, thanks to a pluggable connector with a quick locking system. This luminaire is designed to withstand impacts, and remains hermetically sealed, even when open, preventing dust from entering.

Even the very best housing cannot stand up to the potential effects of an at-risk network. With this in mind, Sammode has opted for the most reliable components available, designed to withstand electrical disturbance, voltage surges and vibrations. The result: a long-lasting solution with an 8-year warranty, including for intensive use.

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Valid even for 24/7 use at the maximum operating temperature for the product. 8-year warranty you will not find anywhere else on the market, reflecting our unfailing commitment to our customers!

Even after 15 or 20 years’ use, every single part we supply can be easily replaced, with no need to send it back to us. No one else offers a guarantee of lifelong lighting solutions!

|

|

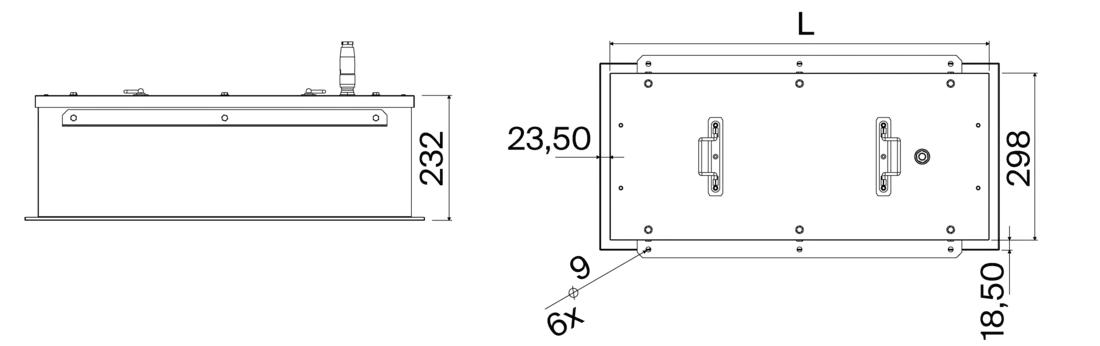

| Flux (lm) | LxlxH (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 3600 | 677x298x232 | CAL 22H840 ME PS3 | 17140020 | 32 | Data sheet | Plan | STEP DS | .TXT | Download all | 7200 | 1277x298x232 | CAL 24H840 ME PS3 | 17140040 | 61 | Data sheet | Plan | STEP DS | .TXT | Download all | 9000 | 1577x298x232 | CAL 25H840 ME PS3 | 17140060 | 77 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

| IP68/69K quick-lock plug with threaded ring (capacity: Ø8 to 10 mm) | PS3 |

| Cover in PMMA IK09 (650°C) | ME |

| Cover in Polycarbonate IK10 (850°C) | PO |

| Frame in Stainless Steel 304L | - |

| Frame in Stainless Steel 316L | MR |

| 3000K | 830 |

| 4000K | 840 |

| 5000K | 850 |

| Electronic gear unit for DALI dimming | RD |

| Light source |

|

| Optics |

|

| Lighting comfort |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Protective cover |

|

| Frame |

|

| Casing, top cover |

|

| Gaskets |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|