Lighting for industrial buildings: Metallurgy & Iron & Steel

Lighting equipment is subjected to extreme conditions on industrial sites in the steel and metallurgy sectors, where several types of stress can affect its lifespan.

Intense heat, dust, vibrations, multi-factor corrosion, oxidation and sometimes even explosive atmospheres (ATEX)... Every production and metal transformation process imposes particularly harsh conditions on the site's lighting equipment. To avoid wasting time and money on maintenance and parts replacement, it's essential to install solid, long-lasting luminaires adapted to each zone and its specific features.

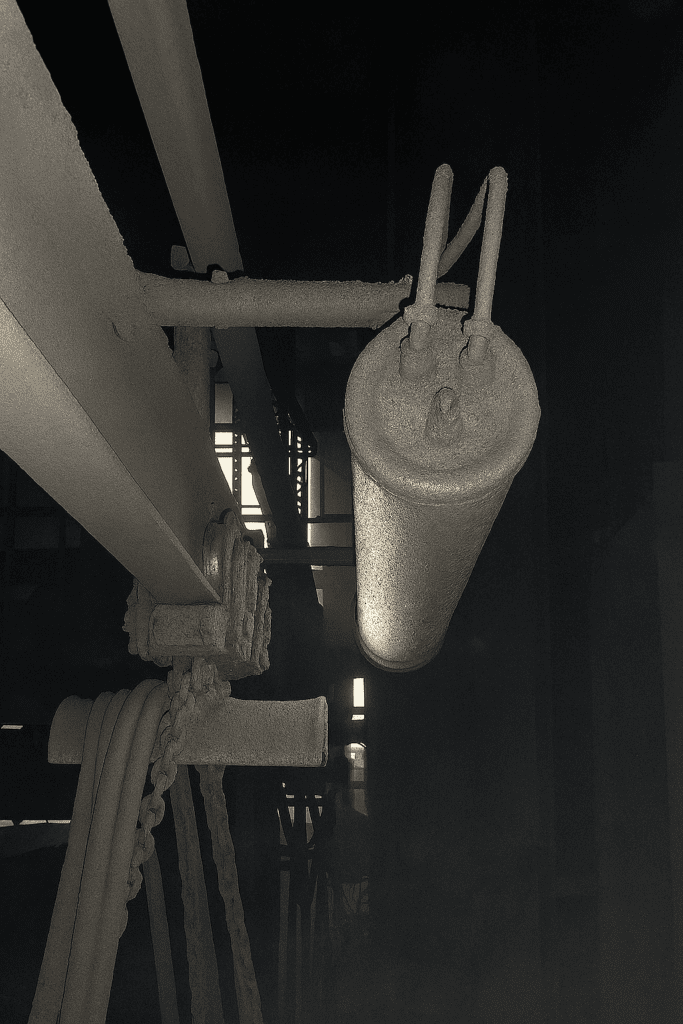

This is where raw materials are transported and stored, before being crushed and sorted. The area where raw materials are received and agglomerated is characterized by the significant and permanent vibrations produced by the imposing transport, extraction and sorting machines (railroads, ships, excavators, giant hoppers, etc.). The high level of dust generated by the handling of large quantities of material also represents a challenge for the equipment present in the area.

To cope with these constraints, we recommend installing tubular luminaires from the CUGNOT Xtrem range for proximity lighting, and SILL 48 and SILL 176 spotlights for remote lighting. In addition to the outstanding waterproofing characteristic of all Sammode products, these lights are designed in one-piece enclosures, so that vibrations do not propagate through the luminaire. Their electronic components are mechanically reinforced to withstand the most intense vibrations.

Requirements

- Intense, permanent vibration

- Dust and dirt

- UV and weather exposure

- Exposure to seaside corrosion

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

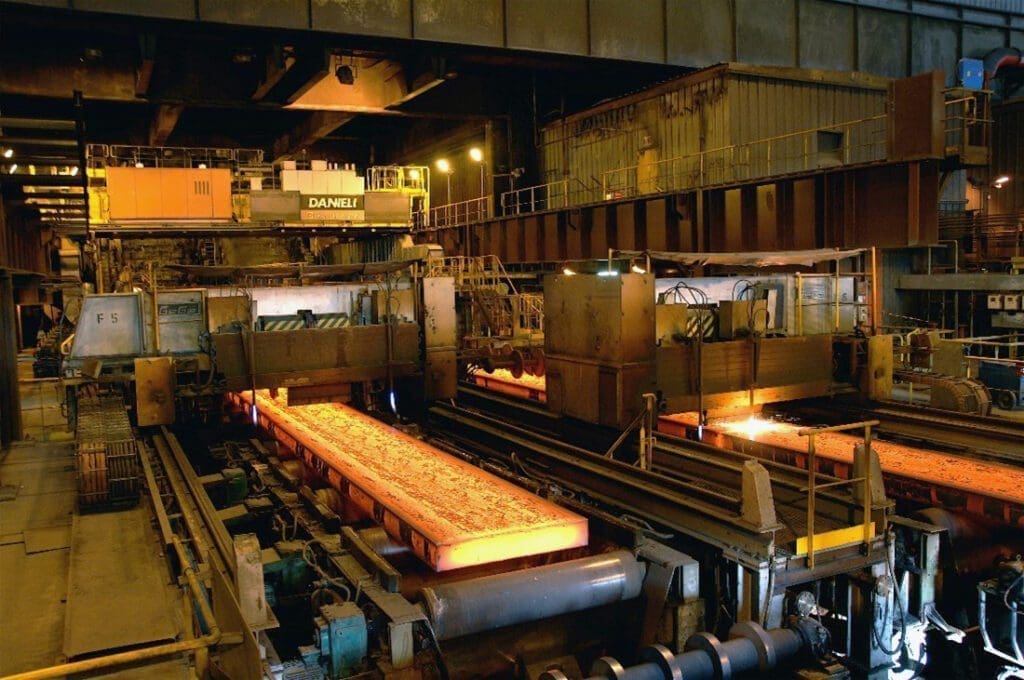

The coking plant, blast furnaces and steelworks are areas of extreme heat. This is where materials are melted down and processed. In addition to the technical challenge of lighting located in such a hot zone, we also have to take into account the chemical aggression associated with corrosive particles emitted by the material and the transformation processes, as well as explosive atmospheres (ATEX). The air in these areas is often charged with flammable particles (dust, gas), requiring absolute reliability of electrical equipment, for obvious safety reasons.

In this sensitive area, you need to adapt your lighting equipment to the proximity of the constraints. In the hottest areas, you can rely on the JOULE X-Heat luminaire or the LESLIE X-Heat model (with its corrosion-resistant glass bowl); and on the BOYLE Xtrem or SABATIER Xtrem tubular luminaires, in the event of an explosive atmosphere (ATEX).

Requirements

- Extreme heat

- Corrosion mutificateur

- Explosive atmosphere (ATEX)

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

- Joule X-Heat

High temperature ø133 tube light for extreme industrial atmospheres

- Leslie X-Heat

High temperature borosilicate glass tube ø133 for highly corrosive atmospheres

- Pauli HT200 X-Heat

Very high temperature ø133 incandescent tube light

- Boyle Xtrem

Borosilicate glass tube ø100 and ø133 for extreme or highly corrosive ATEX zone 2, 21 and 22 atmospheres

- Sabatier Xtrem

Borosilicate glass tube ø133 for extreme or highly corrosive ATEX zone 1 atmosphere

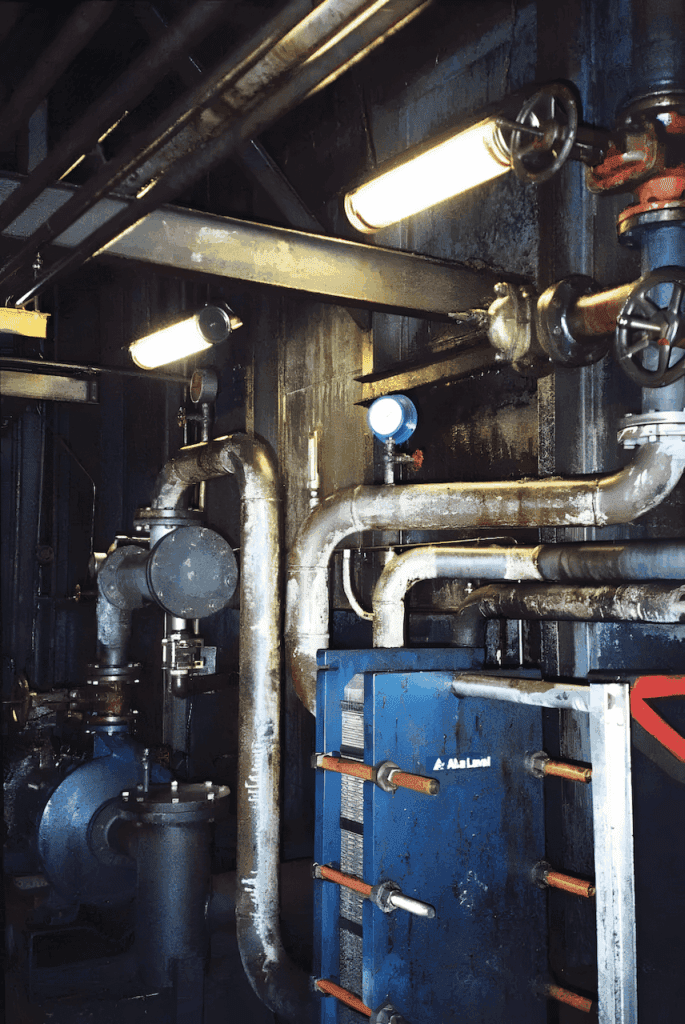

In this area, metal is heated, transformed, cooled, cut and treated with particularly corrosive chemicals. The proximity of continuous casting and hot-rolling strips accentuates the presence of corrosive fumes.

The use of power machines in this area also generates electrical disturbances that require lighting equipment with reinforced electronics.

CUGNOT Xtrem, JOULE X-Heat and LESLIE X-Heat tubulars, as well as SILL industrie 48 floodlights, with their corrosion-resistant surface coatings, meet these requirements perfectly, ensuring reliable, long-lasting lighting for industrial sites.

Requirements

- Corrosion

- Electrical disturbances

- Heat

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

- Joule X-Heat

High temperature ø133 tube light for extreme industrial atmospheres

- Leslie X-Heat

High temperature borosilicate glass tube ø133 for highly corrosive atmospheres

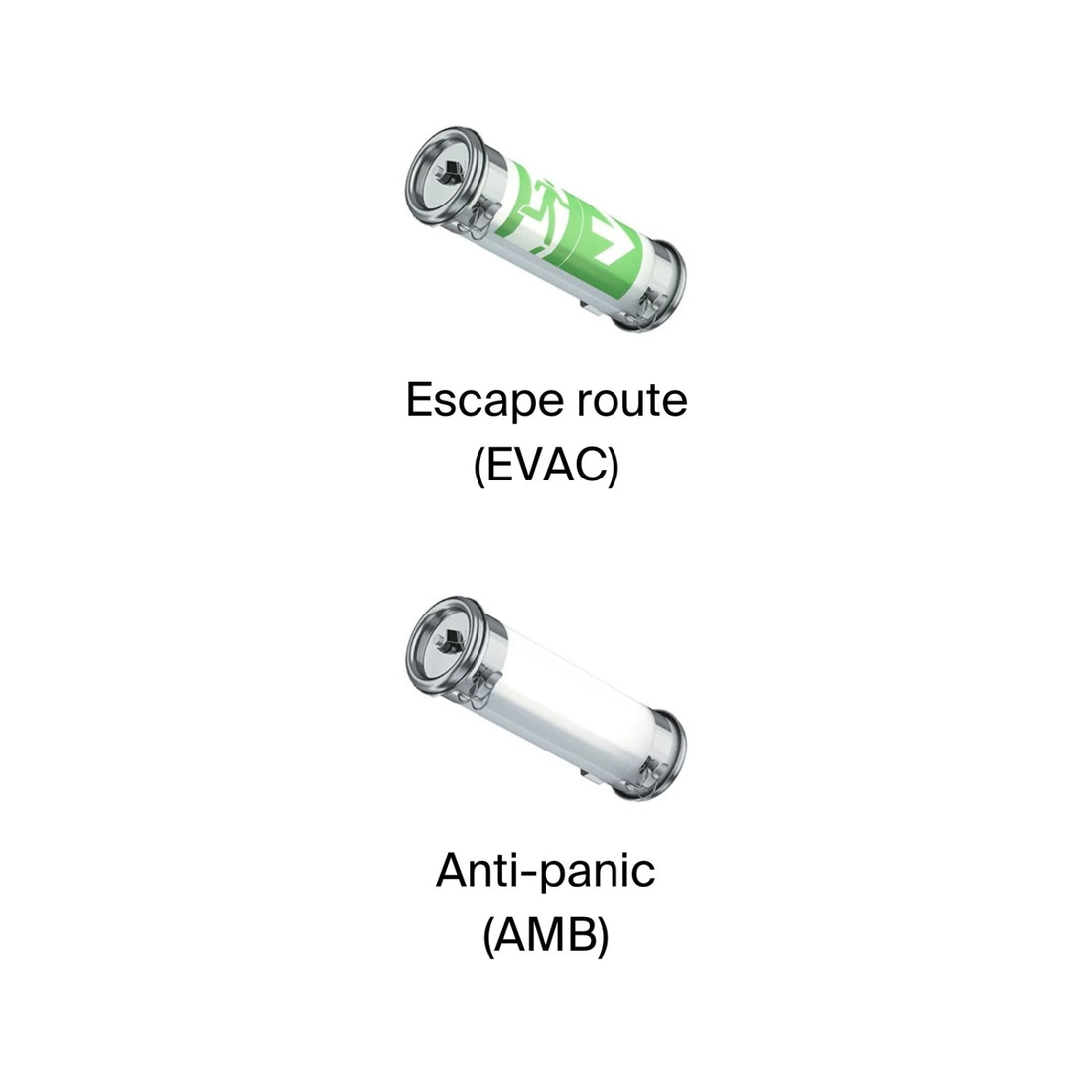

The installation of emergency lighting luminaires, whether they be emergency lighting units (ELU), centralized source luminaires (CSL) or replacement lighting, is both a legal obligation and a safety necessity. They guarantee permanent visibility of production areas, traffic routes and emergency exits on industrial sites, in the event of a power failure. To achieve this, they have to be adapted to current standards, to the constraints of the area in which they are installed and, of course, powered by means other than the industrial site's central network.

COULOMB and MAXWELL emergency lighting luminaires offer the same guarantees of solidity and durability as our other industrial lighting systems, thanks in particular to the quality of the Sammode envelope, renowned for its waterproofing and robustness. Thanks to their batteries (BAES) or their connection to a secondary emergency network (LSC), they can provide evacuation lighting (EVAC) or ambient lighting (AMB) in the event of failure of the main network.

In ATEX zones, the BOYLE tubular also offers an optional replacement lighting function (1h Lithium-ion batteries), so that important work can be completed in the event of a power failure.

Requirements

- Supplied by a source other than the main power grid

- Adapted to the constraints of the area in which they are located

- EN 60 598-2-22 compliant and NF AEAS certified (France)

- Explosive atmospheres (ATEX)

Recommended products

- Boyle Xtrem

Borosilicate glass tube ø100 and ø133 for extreme or highly corrosive ATEX zone 2, 21 and 22 atmospheres

In order to access industrial sites and move around safely, personnel need lighting in large outdoor areas (parking lots, stairways, passageways, building approaches, etc.). These lights are often installed in particularly difficult-to-access areas, often at height. To limit maintenance and optimize operating costs, industrial sites need to install lighting equipment that is particularly efficient, reliable and long-lasting. The solutions installed must also offer the right power and photometry for the area to be lit, in order to ensure a sufficient level of illumination with good uniformity, and thus avoid shadow zones.

We recommend the installation of SILL 176 and 177 spotlights on masts, crosses and pylons, and the use of CUGNOT Xtrem tubular luminaires for proximity lighting (walkways, stairways, gangways, building footings). Both ranges combine robust electronics with high resistance to corrosion.

Requirements

- Height

- Complicated accessibility

- Efficient brightness and photometry

- UV and weather exposure

- Exposure to seaside corrosion

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

Designed for extreme environments.

IK10 –Vibrations and shocks

Resistance to high intensity vibrations and shocks (IEC 60068-2-6).

UV

Body made of co-extruded polycarbonate/methacrylate, providing durable resistance to acids and UV.

Resistance to high temperatures

Up to +200°C with a laminated glass body. LED lighting solutions resistant up to +70°C. Enclosure system absorbing the effects of thermal variations.

Sammode expertise

Diagnosis and recommendations

We start by analysing your operating conditions, installation requirements and other specific needs, and then recommend the most suitable solutions.

Lighting studies

Our lighting studies are designed to identify the precise quantity of luminaires and quality of the lighting solution required, while minimsing the number of light sources and energy use.

Control systems

To reduce your energy bill and improve your lighting control, our experts will suggest the management solutions best suited to your situation.

Developing special products

As both designer and manufacturer, we systematically study the best technical solutions and are able to adapt them to meet your needs.

On-site testing and support

We can manage your project from start to finish, from studies to installation, including any tests required in actual operating conditions.

Ultimate 8-year warranty

We offer an ultimate 8-year warranty for most of our products, the only such offer available on the lighting market under intensive 24/7 operating conditions.

They trust us