Leslie X-Heat

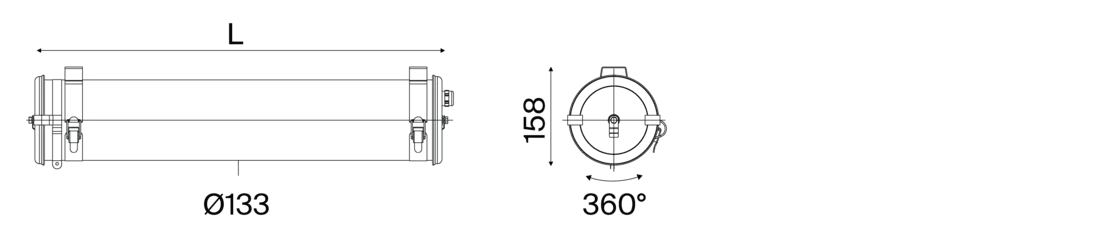

High temperature borosilicate glass tube ø133 for highly corrosive atmospheres

The ultimate lighting option, up to 200°C

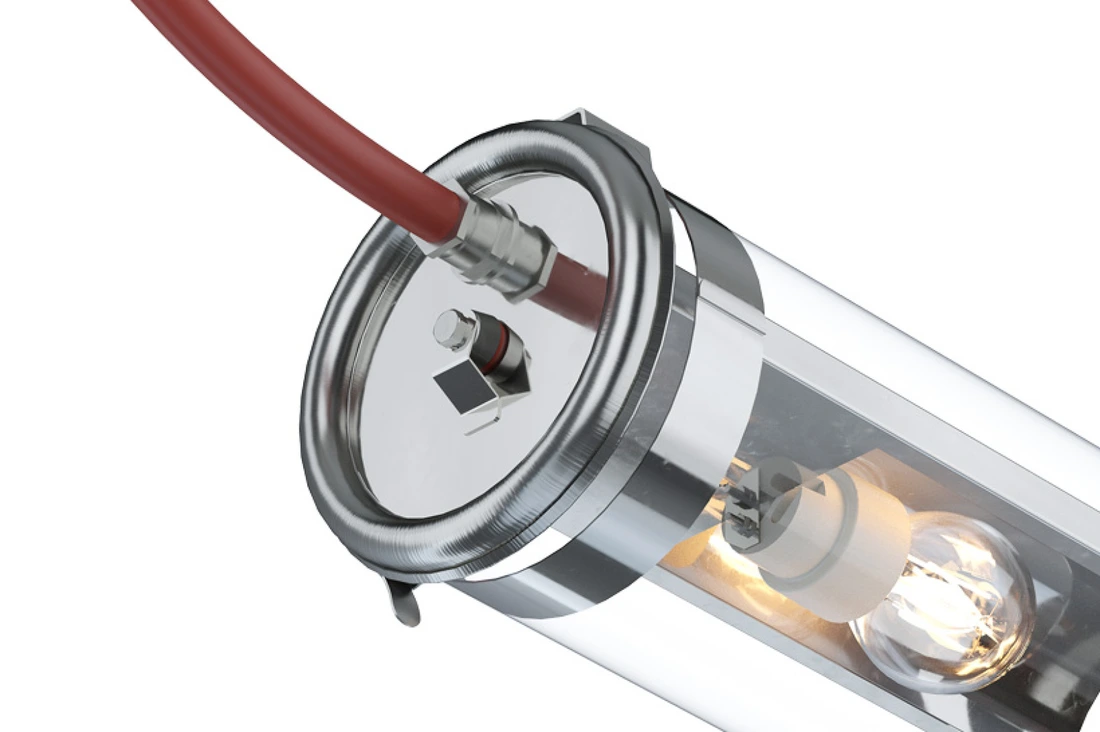

Providing light, even in places operators can’t go... The Pauli HT200 designed for industrial furnaces provides an ideal option thanks to the use of materials able to withstand both temperatures and corrosion. This tubular light with incandescent bulbs is completely sealed thanks to its one-piece structure, and benefits from exceptional durability.

Highly corrosive or abrasive environments

Splashes of very hot liquids

Flame-resistant, inflammable

Oils & hydrocarbons

Dust and extreme grime

All types of humidity

Very hot, humid or dry atmosphere

Washing with a high-pressure jet

Permanent use at temperatures of up to 200°C

Thermal shocks

Mechanical impacts

Intense and repetitive vibrations

This luminaire, with its compact ultra-solid housing for 1 or 2 E27 bulbs specifically designed for furnaces, is emblematic of the century-old expertise held by Sammode. This unit is non-flammable and hard-wearing and can offer long-lasting lighting for the most extreme industrial processes, in places operators just cannot tread.

Forget very hot vapours, fine dust, glowing particles and the like: this luminaire is IP68 & IP69K certified. Thanks to its high-temperature silicone gaskets and uniform tightening with a central screw (the Screw© system), the housing remains firmly sealed, even when the temperature varies significantly.

Exceptional long-lasting strength, thanks to a 100% stainless steel and borosilicate glass housing (IK07) resistant to heat and corrosion. The internal stainless steel gear tray houses the ceramic sockets, an aluminium reflector and woven fibreglass cloth cabling, ensuring strength up to 200°C.

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Valid even for 24/7 use at the product’s maximum operating temperature, reflecting our unfailing commitment to our customers!

Even after 15 or 20 years’ use, every single part we supply can be easily replaced, with no need to send it back to us. No one else offers a guarantee of lifelong lighting solutions!

|

|

| Number of lamps | L (mm) | Flux (lm)** | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 1 | 464 | 390 | PAU133 HT200 1x60W E27 PY 113LN BRS | 36170011 | 60 | Data sheet | Plan | STEP DS | .TXT | Download all | 2 | 677 | 780 | PAU133 HT200 2x60W E27 PY 113LN BRS | 36170021 | 120 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

| Nickel-coated brass capacity Ø5-8 mm | 113LN |

| Nickel-coated brass capacity Ø5-8 mm | 213LN |

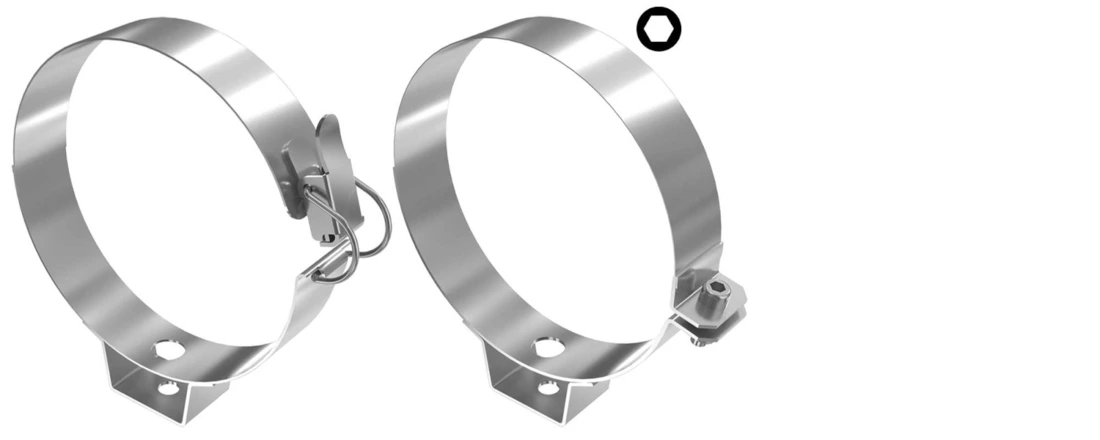

| Reinforced fixing straps | BRS |

| Reinforced fixing straps with HSHC screw | BRV |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

1m HO7-RNF pre-wired high temperature cable 3G1,5²

1m HO7-RNF pre-wired high temperature cable 3G1,5²

| Stripped free end CAB0076 |

| Light source |

|

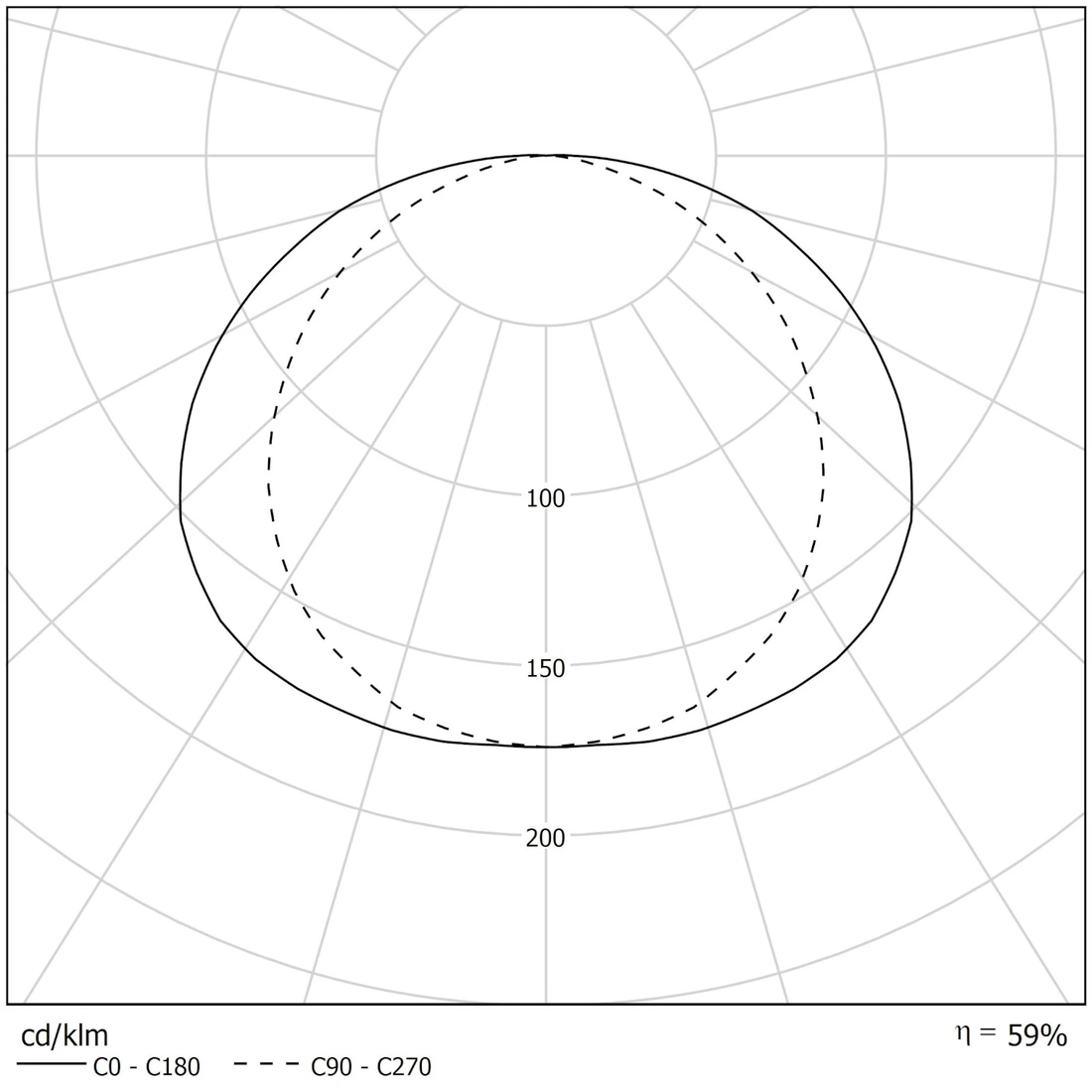

| Optics |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Lighting comfort |

|

| Connection |

|

| Mounting |

|

| Maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Gaskets |

|

| Method of construction |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|