Cugnot Xtrem

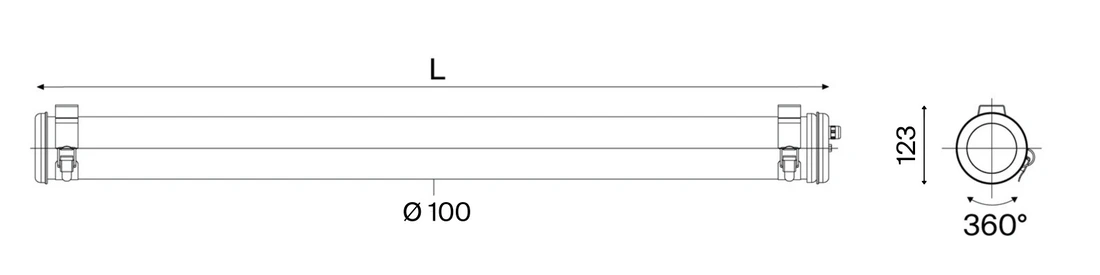

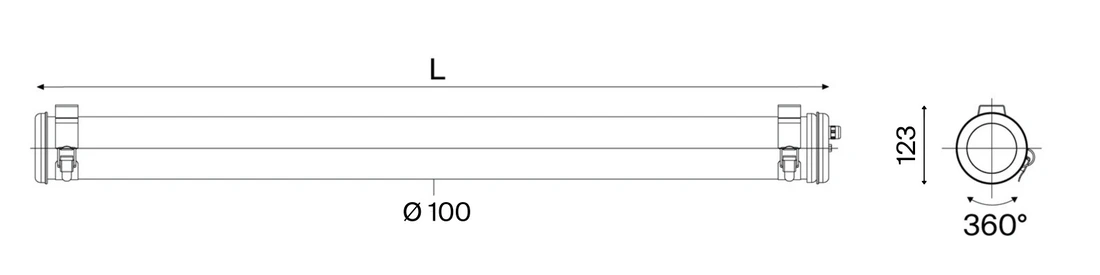

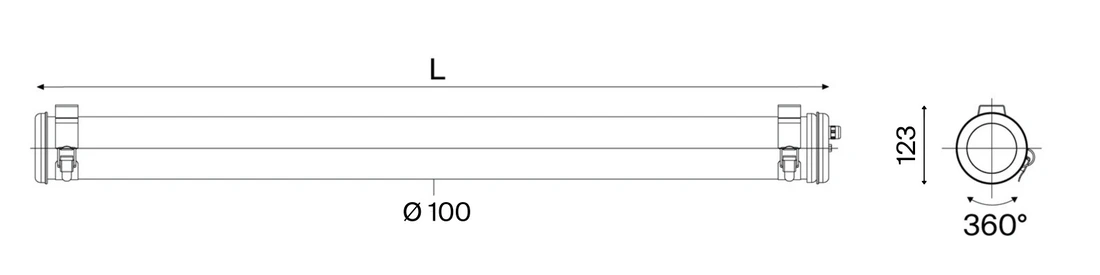

ø100 and ø133 tube light for extreme industrial atmospheres

A versatile luminaire engineered to withstand the most demanding environments.

The Carnot is a versatile luminaire designed to withstand the most demanding environments. It is immune to shocks, humidity, high-pressure cleaning and UV exposure, and delivers outstanding light quality and energy performance meeting the highest standards, supported by ENEC third-party certification. Its sliding gear tray ensures fast and ergonomic installation. Its ultra-reliable electronics — as robust as a traditional magnetic ballast — guarantee minimal maintenance over decades.

Dust, humidity

High-pressure jet cleaning

Hygiene requirements according to IFS, BRC and HACCP standards

Corrosive agents, acidic vapours

Oils & hydrocarbons

UV exposure and weather conditions

Continuous operation at temperatures up to 50°C

Voltage peaks up to 4 kV, overvoltage

Frequent switching on and off

Severe mechanical impacts

Designed for the most demanding environments, the Carnot withstands shocks, humidity, high-pressure cleaning and UV exposure. Its sealed and robust construction ensures long-lasting reliability, even in the harshest ambient conditions.

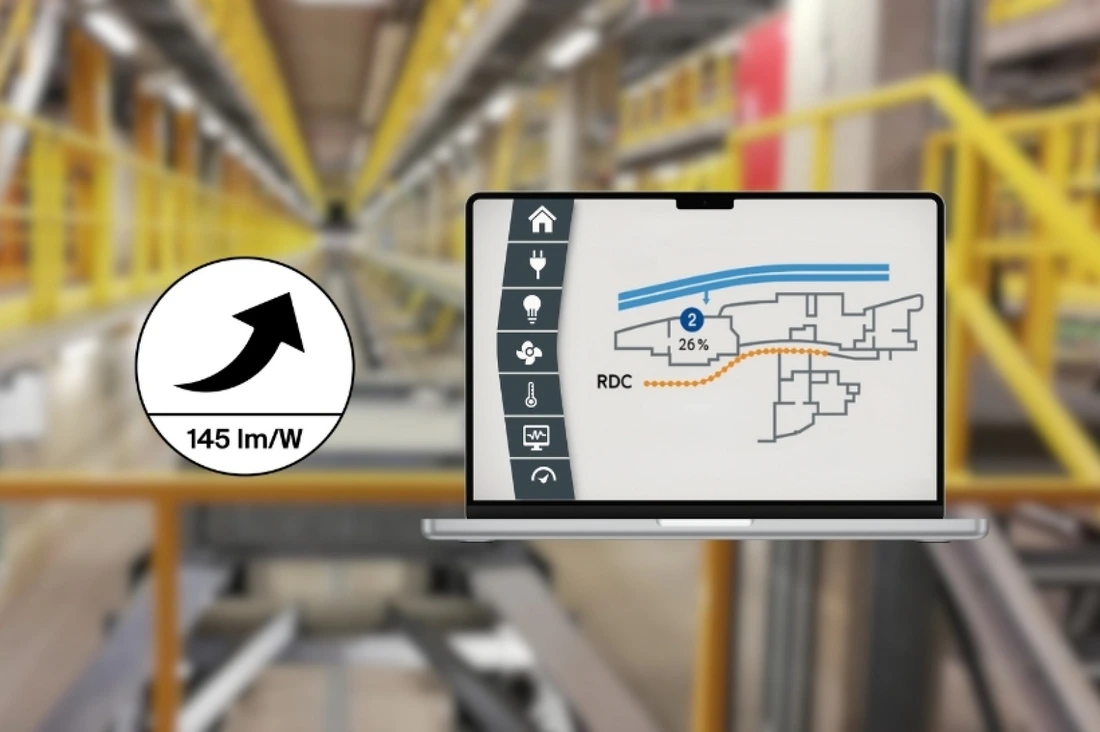

Thanks to a design combining durability and energy performance, the Carnot tubular luminaire delivers optimal long-term efficiency, reaching up to 145 lm/W. ENEC certified, it guarantees safety, operational peace of mind and consistent performance over time.

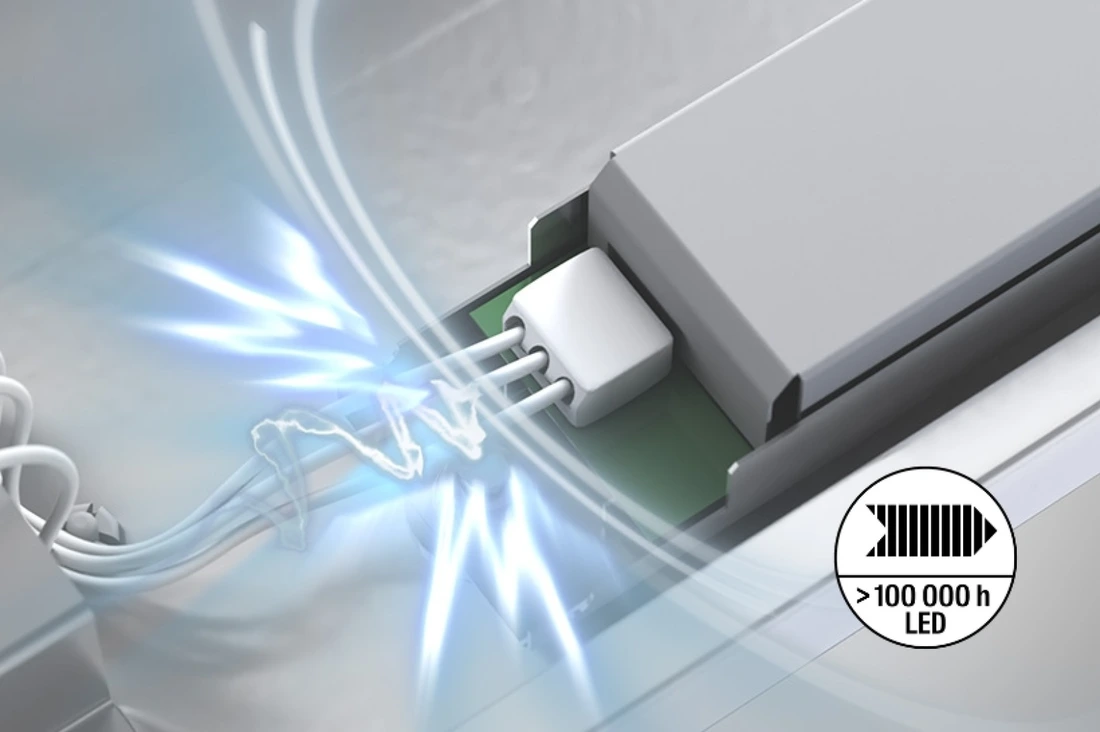

The Carnot incorporates electronics of unmatched robustness (driver lifetime > 100,000 h), as resilient as a magnetic ballast. Designed to withstand time, electrical disturbances, voltage peaks and temperature variations, it minimises maintenance requirements and ensures long-term luminous stability.

With its sliding gear tray and integrated through-wiring option, the Carnot simplifies every installation step. Its smart engineering ensures a fast, safe and flexible setup, even in the most complex configurations.

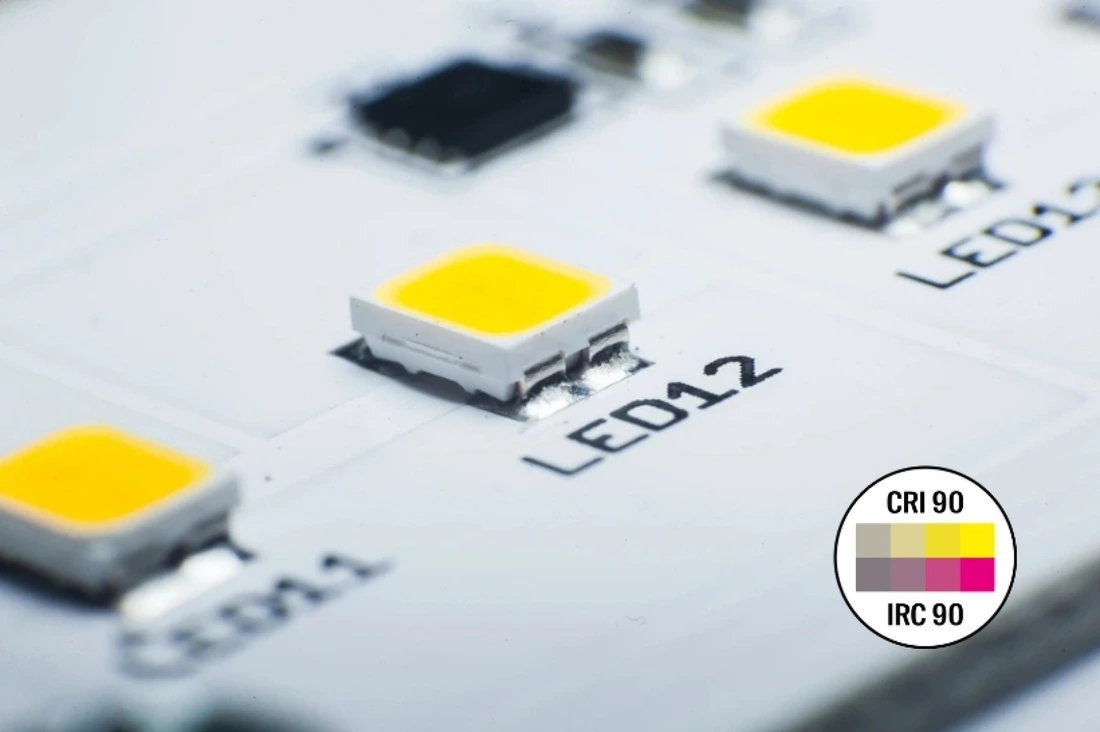

Available in a high-colour-quality version, the Carnot delivers exceptional colour rendering (CRI 90) and outstanding visual comfort. Compliant with Deutsche Bahn standards, it meets the requirements of both technical and public-facing environments.

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Valid even for 24/7 use at the maximum operating temperature for the product. 8-year warranty you will not find anywhere else on the market, reflecting our unfailing commitment to our customers!

Unlike the disposable world we live in, Sammode lights are designed as modular systems. New technology can be integrated in existing fixtures: simply replace the outdated parts!

|  |  |

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 3700 | 1318 | CAR100 1300 3700-840 RD POME 113 BRS ENEC | 31120034 | 26 | Data sheet | Plan | STEP DS | .TXT | Download all | 4625 | 1618 | CAR100 1600 4625-840 RD POME 113 BRS ENEC | 31120040 | 32 | Data sheet | Plan | STEP DS | .TXT | Download all | 5550 | 1850 | CAR100 1850 5550-840 RD POME 113 BRS ENEC | 31120058 | 38 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

|  |  |

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 3700 | 1318 | CAR100 1300 3700-840 RD CL2 POME 113 BRS ENEC | 31120004 | 26 | Data sheet | Plan | STEP DS | .TXT | Download all | 4625 | 1618 | CAR100 1600 4625-840 RD CL2 POME 113 BRS ENEC | 31120005 | 32 | Data sheet | Plan | STEP DS | .TXT | Download all | 5550 | 1850 | CAR100 1850 5550-840 RD CL2 POME 113 BRS ENEC | 31120006 | 38 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

|  |  |

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 1850 | 708 | CAR100 700 1850-940 CL2 POME 113 BRS ENEC | 31120007 | 17 | Data sheet | Plan | STEP DS | .TXT | Download all | 2775 | 1018 | CAR100 1000 2775-940 CL2 POME 113 BRS ENEC | 31120008 | 25 | Data sheet | Plan | STEP DS | .TXT | Download all | 3700 | 1318 | CAR100 1300 3700-940 CL2 POME 113 BRS ENEC | 31120002 | 33 | Data sheet | Plan | STEP DS | .TXT | Download all | 4625 | 1618 | CAR100 1600 4625-940 CL2 POME 113 BRS ENEC | 31120009 | 39 | Data sheet | Plan | STEP DS | .TXT | Download all | 5550 | 1850 | CAR100 1850 5550-940 CL2 POME 113 BRS ENEC | 31120010 | 46 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

| Polyamide capacity Ø7-12mm | 113 |

| Polyamide capacity Ø8-14mm | 116 |

| Nickel-coated brass capacity Ø5-14 mm | 113LN |

| Polyamide capacity Ø7-12mm | 213 |

| Polyamide capacity Ø8-14mm | 216 |

| Nickel-coated brass capacity Ø5-14 mm | 213LN |

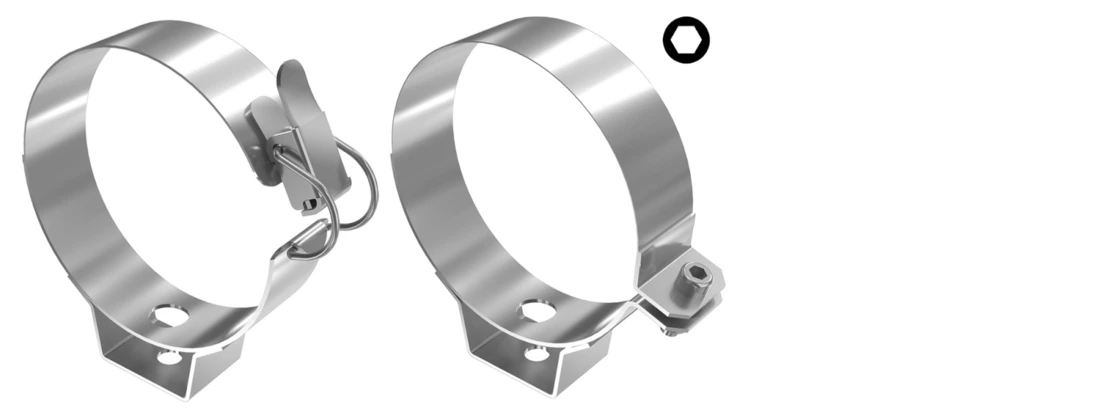

| Reinforced fixing straps | BRS |

| Fixing straps with HSHC screw | BRV |

| Polycarbonate housing | PO |

| Coextruded polycarbonate/ PMMA housing with high chemical resistance | POME |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

| 3000K | 830/930 |

| 4000K | 840/940 |

| Non dimmable | - |

| Electronic gear unit for DALI 2 dimming | RD |

| IP68 4-outlet junction box (capacity Ø7-14mm) CP00674 |

| 2 x 20 cm 304L stainless steel extensions PU44277 | |

| 2 x 5 cm 304L stainless steel extensions PU44278 |

| Light source |

|

| Optics |

|

| Lighting comfort |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Method of construction |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|

| Certification |

|

|