Lighting: nuclear power stations will have to switch to LEDs

As part of a European regulation advocating more sustainable installations, the lighting industry is gradually phasing out the marketing of lamps with poor environmental performance, such as fluorescent tubes. This law will have a major impact on nuclear power plants (CNPE), which must now turn to LED solutions. To make this conversion as successful as possible, CNPE technical teams have called on lighting experts such as Sammode, which develops ultra-durable LEDs adapted to the extreme conditions of nuclear power plants.

This year, hundreds of millions of end-of-life fluorescent lamps and tubes will have to be replaced in France. This obligation is part of European regulations (Regulation (EU) 2019/2020 and European Directive 2011/65/EU on the reduction of hazardous substances) aimed at promoting more sustainable lighting.

The lighting industry will therefore be putting an end to the marketing of these energy-guzzling lamps with poor environmental performance. Long-life fluorescent tubes and compact fluorescent lamps with non-integrated control gear (CFL-ni) rated at less than 20,000 hours have already been banned from sale since 24 February.

On 24 August, T5/T8 fluorescent tubes and compact fluorescent lamps with a life of more than 20,000 hours will also be withdrawn from the market. Seven days later, halogen capsules with G9 G4 GY 6.35 bases will no longer be sold.

Professionals looking for an equivalent can choose from a wide range of LED (light-emitting diode) solutions. The catalogue of LED lighting products has been expanded to offer a complete range of lamps and/or luminaires.

The result of innovations by manufacturers, this development is a response to the challenges of energy efficiency and environmental protection. The aim is threefold: to consume fewer resources and reduce energy bills, while improving the use and quality of light.

LED luminaires fully meet these objectives, since they offer substantial energy savings, averaging 50%. This is a major advantage at a time when energy costs have risen sharply. What's more, LED lighting lasts up to 5 times longer than fluorescent tubes. A performance that reduces maintenance and replacement costs. LEDs also provide great comfort for the eyes, thanks to their luminous stability.

LEDs are also environmentally friendly lighting. Fluorescent tubes emit light via a chemical reaction, whereas LEDs contain no chemical substances. The components of LED technology are also recyclable.

Professionals therefore have everything to gain by favouring LEDs. However, some sectors, such as the nuclear industry, which operates in a constrained and dangerous environment, need to proceed with caution when converting to LED lighting.

To achieve this, the technical teams at nuclear power plants (CNPE) can count on Sammode, a long-standing partner in the lighting sector for 50 years. As a French designer and manufacturer, Sammode now equips 40% of France's nuclear power plants. This makes Sammode the leader in lighting for nuclear power plants.

Sammode is developing ultra-durable LED luminaires (guaranteed for 10 years - 90,000 hours of operation) adapted to the variable and extreme conditions in the different areas of nuclear power plants and their specific problems (chemical, mechanical, electrical, sealing, etc.).

The company offers reliable, safe and durable LED conversion at the best price. Nuclear power plants save on installation costs and maintenance operations because Sammode retains the original lighting by replacing only the source (PCB) with an LED module. This not only saves money, it also saves time thanks to the rapid installation of an LED kit.

The reliability of Sammode LEDs is a key criterion, since the nuclear sector involves a number of constraints. First and foremost, they have to be durable, as the luminaires are difficult to access in nuclear power plants and are sometimes located in irradiated areas. It is therefore advantageous not to have to carry out regular maintenance. Not to mention the much lower maintenance and replacement costs.

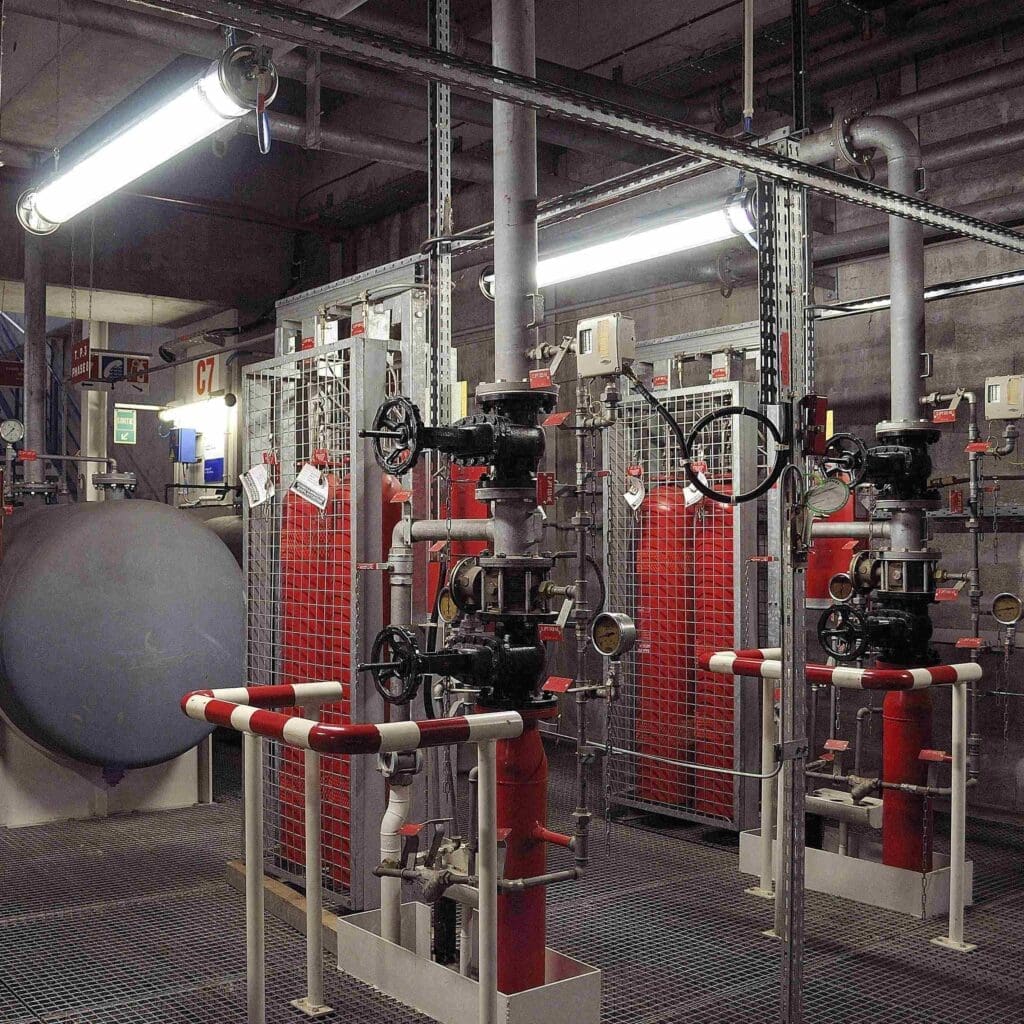

In addition, the cooling towers, used to cool the plant's secondary circuits by evacuating steam, are very damp, subject to limestone-laden run-off and high temperatures. The machine rooms are also subject to flying parts.

Electrical buildings can experience electrical disturbances. Water treatment plants and pumping stations are acidic and corrosive environments. Battery rooms and diesel sites are also potentially explosive areas.

Sammode, a company recognised throughout France and Europe as an expert in industrial lighting, offers luminaires that comply with CNPE requirements. For example, they are resistant to shocks, earthquakes, explosive environments, humidity, excess pressure, gamma radiation and temperature rises.

Thanks to Sammode, nuclear power plants are making profits well in excess of the investment required to convert their sites to LEDs. For 4,000 light points in a nuclear power plant, savings of €1.2 million can be made over 10 years, including €250,000 in energy savings and €950,000 in purchase and maintenance costs.