Boyle True Colours

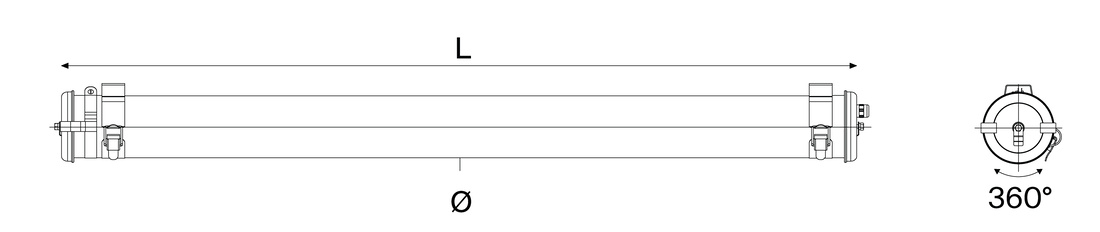

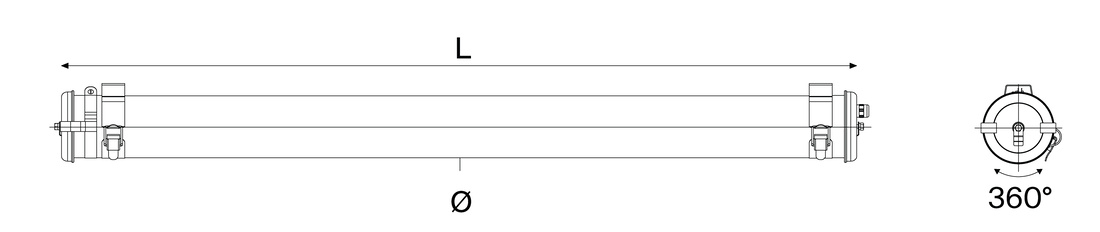

CRI 95 borosilicate glass tube ø100 and ø133, ideal for paint booths ATEX zone 2, 21 and 22 atmospheres

High color fidelity and high cleanability lighting for ATEX zones 2, 21 and 22

Explosive gas environments, zone 2, Dust environments, zones 21 & 22

The Boyle True Colours is a unique luminaire on the market, combining exceptional light quality with unmatched durability to equip ATEX Zones 2, 21 and 22. Designed for the most demanding environments, it stands out as the ideal solution for paint booths—particularly in the aeronautical and automotive industries—and wherever precise colour rendering is critical. With its Pyrex glass envelope and smooth, asperity-free stainless steel structure, it ensures optimal cleanability.

Extreme dust exposure and heavy soiling

Humidity in all its forms

High-pressure water jet cleaning

Use of cleaning or stripping agents such as acetone

Permanent use at temperatures of up to 50°C

Extreme variation in temperature

Repeated turning on and off

Mechanical impacts Intense and repetitive vibrations

Voltage surges up to 4 kV, power surges

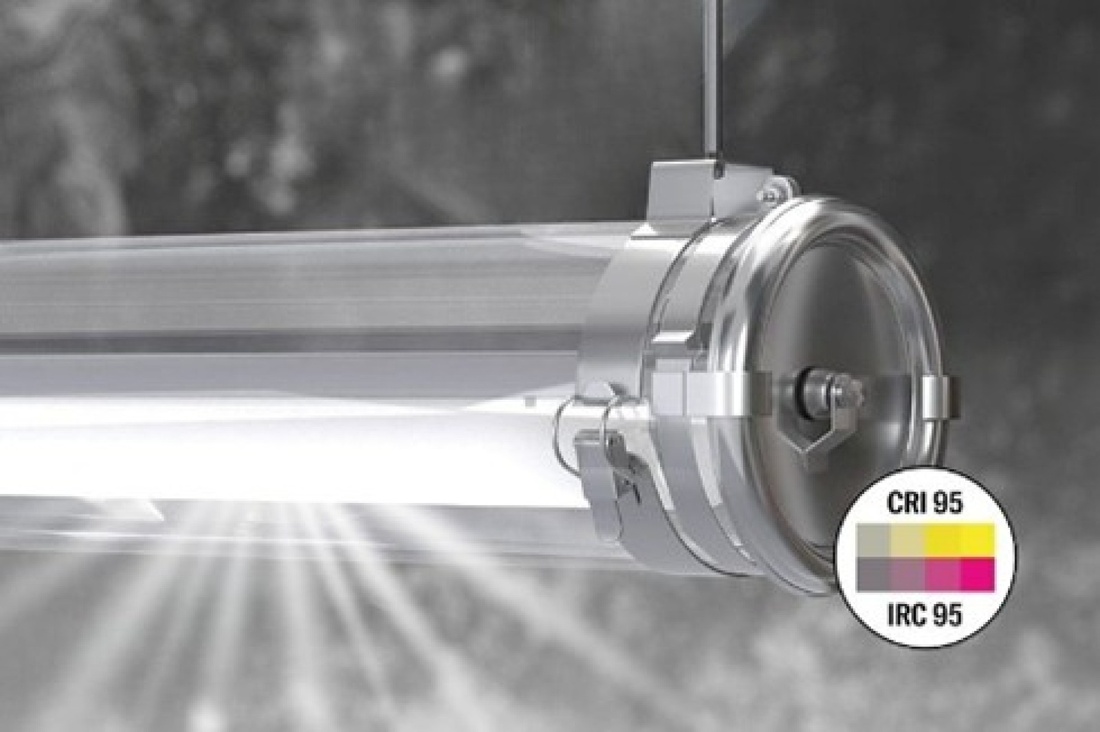

The tubular Boyle True Colours delivers outstanding light precision, perfectly calibrated for colour inspection operations in paint booths. With a CRI 95 compliant with ISO 3664 and ISO 3668 standards, it ensures faithful colour rendering and reliable colour validation. This level of light quality is a decisive advantage for sectors where colour accuracy directly determines final quality. Boyle True Colours therefore becomes an essential tool to guarantee a compliant, uniform and impeccable finish in ATEX environments.

The Boyle True Colours luminaire is designed to deliver exceptional long-term performance, thanks to a mechanically robust housing and a controlled weight that facilitates maintenance. Its high-reliability driver ensures consistent luminous performance, even under intensive use, meeting the continuous demands of paint booths. This durable design guarantees optimal light quality year after year, backed by an 8-year warranty. To support this longevity, the availability of key components is guaranteed for 30 years, ensuring reliable and sustainable maintenance.

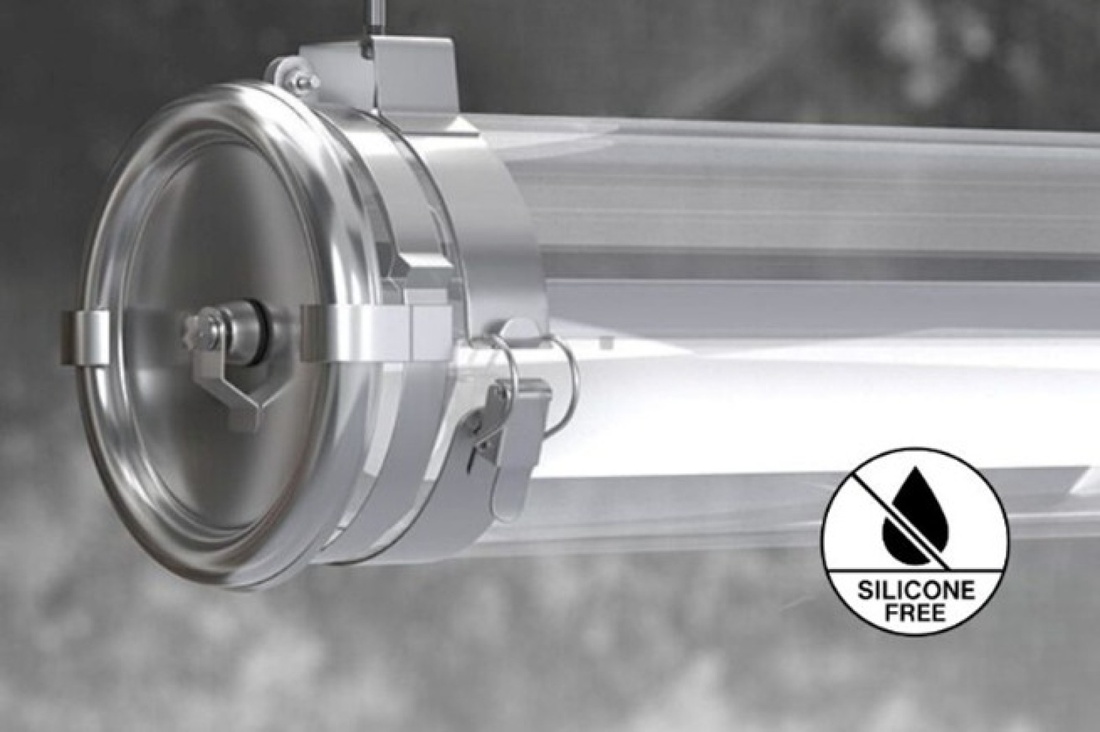

Featuring a borosilicate glass (Pyrex) envelope and a smooth, asperity-free stainless steel structure, Boyle True Colours delivers exemplary cleanability, essential for removing paint build-up in paint booths or in ATEX environments requiring frequent cleaning. These smooth, non-porous materials are resistant to the cleaning agents used during decontamination. The luminaire integrates triple-seal gaskets, preventing any ingress of water, humidity or dust. This design ensures easy maintenance, enhanced durability and preserved performance in the most demanding paint booth and ATEX environments.

Certified for continuous operation up to +50 °C, Boyle True Colours delivers outstanding thermal stability, even in paint booths where heat levels can be particularly high. Its design ensures controlled heat dissipation, preserving LED driver performance over time. Equipped with an LED driver engineered to deliver 70,000 hours of operation under these extreme conditions, the luminaire maintains exceptional performance consistency. This thermal robustness makes it a reliable and safe solution for the most demanding environments.

The tubular Boyle True Colours luminaire is designed with no use of silicone, in full compliance with the strict requirements of professional paint booths. This feature eliminates any risk of surface contamination and ensures perfect compatibility with sensitive industrial processes. The absence of silicone reinforces the luminaire’s relevance in environments where finish quality is non-negotiable. A safe, controlled solution fully adapted to the constraints of the sector.

The Boyle True Colours benefits from ATEX certification issued by an independent body, ensuring an exceptionally high level of compliance. This external validation confirms the luminaire’s safety for use in ATEX Zones 2, 21 and 22, where regulatory requirements are particularly stringent. Thanks to this third-party expertise, users are assured of reliable, controlled and fully secure lighting. Boyle True Colours therefore stands as a benchmark solution for environments with explosive atmospheres.

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Product with Atex certification for gas zones 2 and dust zones 21 & 22, issued by an independent laboratory. 8-year warranty you will not find anywhere else on the market, valid even for 24/7 use at the product’s maximum operating temperature.

Even after 15 or 20 years’ use, every single part we supply can be easily replaced, with no need to send it back to us. No one else offers a guarantee of lifelong lighting solutions!

|  |  |

| Ø (mm) | Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 100 | 1700 | 697 | BOY100 700 1700-9565 PY 113 BRS | 19835547 | 19 | Data sheet | Plan | STEP DS | .TXT | Download all | 100 | 2600 | 1007 | BOY100 1000 2600-9565 PY 113 BRS | 19835548 | 27 | Data sheet | Plan | STEP DS | .TXT | Download all | 100 | 3500 | 1307 | BOY100 1300 3500-9565 PY 113 BRS | 19835549 | 34 | Data sheet | Plan | STEP DS | .TXT | Download all | 100 | 4400 | 1607 | BOY100 1600 4400-9565 PY 113 BRS | 19835550 | 42 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 3100 | 677 | BOY133 700 3100-9565 PY 113 BRS | 19845562 | 30 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 4600 | 987 | BOY133 1000 4600-9565 PY 113 BRS | 19845551 | 44 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 6100 | 1287 | BOY133 1300 6100-9565 PY 113 BRS | 19845552 | 57 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 7600 | 1587 | BOY133 1600 7600-9565 PY 113 BRS | 19845553 | 71 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

|  |  |

| Ø (mm) | Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all | 100 | 1700 | 697 | BOY100 700 1700-9550 PY 113 BRS | 19835544 | 19 | Data sheet | Plan | STEP DS | .TXT | Download all | 100 | 2600 | 1007 | BOY100 1000 2600-9550 PY 113 BRS | 19835545 | 27 | Data sheet | Plan | STEP DS | .TXT | Download all | 100 | 3500 | 1307 | BOY100 1300 3500-9550 PY 113 BRS | 19835546 | 34 | Data sheet | Plan | STEP DS | .TXT | Download all | 100 | 4400 | 1607 | BOY100 1600 4400-9550 PY 113 BRS | 19835543 | 42 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 3100 | 677 | BOY133 700 3100-9550 PY 113 BRS | 19845563 | 30 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 4600 | 987 | BOY133 1000 4600-9550 PY 113 BRS | 19845548 | 44 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 6100 | 1287 | BOY133 1300 6100-9550 PY 113 BRS | 19845549 | 57 | Data sheet | Plan | STEP DS | .TXT | Download all | 133 | 7600 | 1587 | BOY133 1600 7600-9550 PY 113 BRS | 19845550 | 71 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

|

| Cord length (m) | Designation | Code | Data sheet | Plan | STEP DS | .TXT | Download all | 0,1 | CABL HO7RNF-BK XTREM ATEX-PLUG 0.1M 3G1.5 | CAB0288 | Data sheet | Plan | STEP DS | .TXT | Download all | 1 | CABL HO7RNF-BK XTREM ATEX-PLUG 1M 3G1.5 | CAB0289 | Data sheet | Plan | STEP DS | .TXT | Download all | 3 | CABL HO7RNF-BK XTREM ATEX-PLUG 3M 3G1.5 | CAB0290 | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|

| Polyamide capacity Ø6,5-14mm | 113 |

| Nickel-coated brass capacity Ø6-14 mm | 113LN |

| Polyamide capacity Ø6,5-14mm | 213 |

| Nickel-coated brass capacity Ø6-14 mm | 213LN |

| Reinforced fixing straps | BRS |

| Reinforced fixing straps with HSHC screw | BRV |

| Borosilicate glass housing (IK07) | PY |

| Coextruded polycarbonate/ PMMA housing IK10 | POME |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

| 3000K - CRI 80 | 830 |

| 4000K - CRI 80 | 840 |

| 5000K - CRI 95 | 9550 |

| 6500K - CRI 95 | 9565 |

| Non dimmable | - |

| Electronic gear unit for DALI dimming | RD |

| 1h Self contained Emergency Lighting Long life time LiFePO4 battery Tmax=30°C | S1H |

| DALI addressable version | S1H-A |

HO7-RNF Xtrem pre-wired cable with an IP67/69 Marechal® PNCX Atex disconnectable plug

HO7-RNF Xtrem pre-wired cable with an IP67/69 Marechal® PNCX Atex disconnectable plug | Several length available (6m max), 3 or 5 conductors : consult us |

| Length 800mm PU6362 | |

| Length 1100mm CP00595 | |

| Length 1400mm PU6286 | |

| Length 1700mm PU6363 |

| Adapter ø1"1/4 (=42mm) PU4321 | |

| Adapter ø1"1/2 (=49mm) PU4083 | |

| Adapter ø2" (=60mm) PU4082 |

| Light source |

|

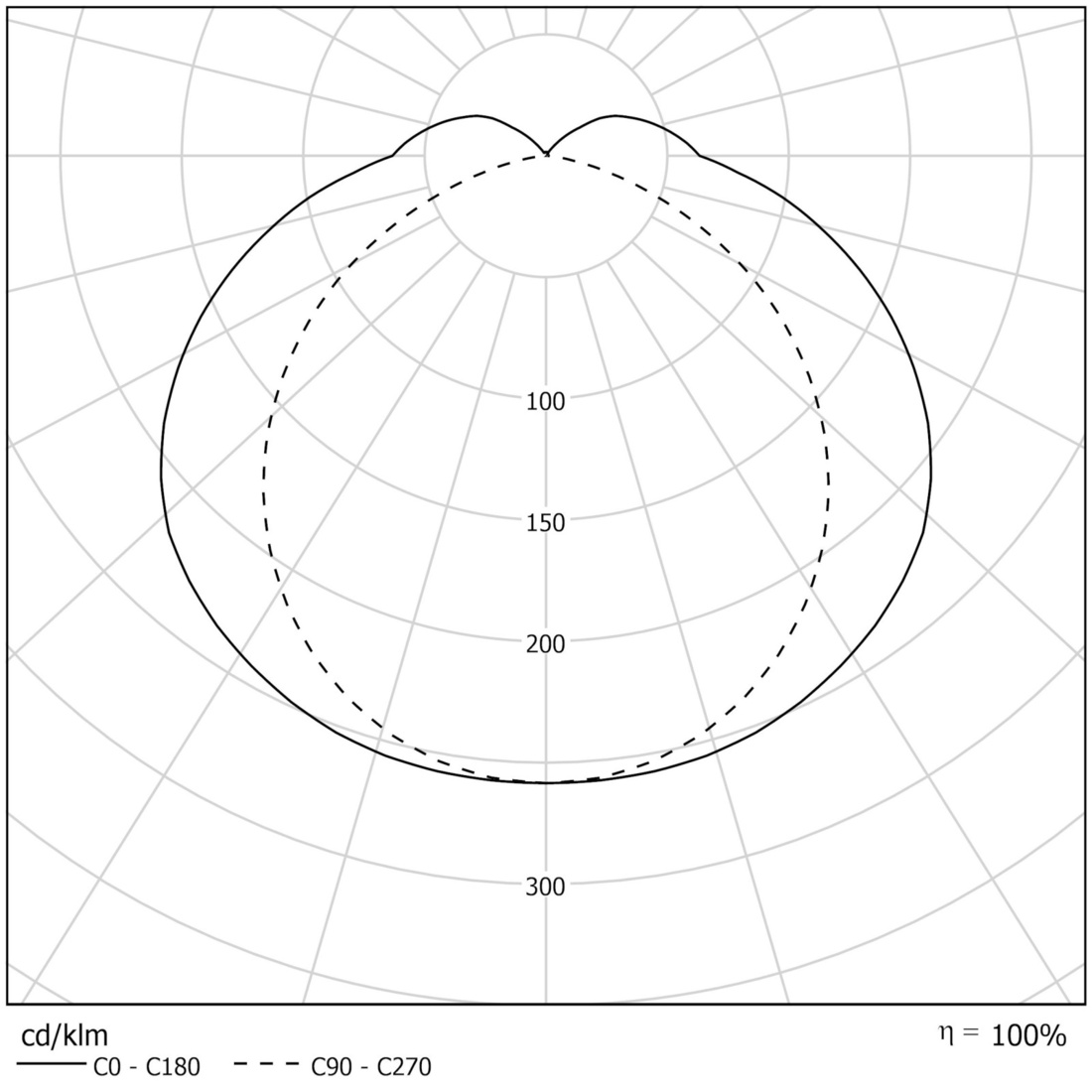

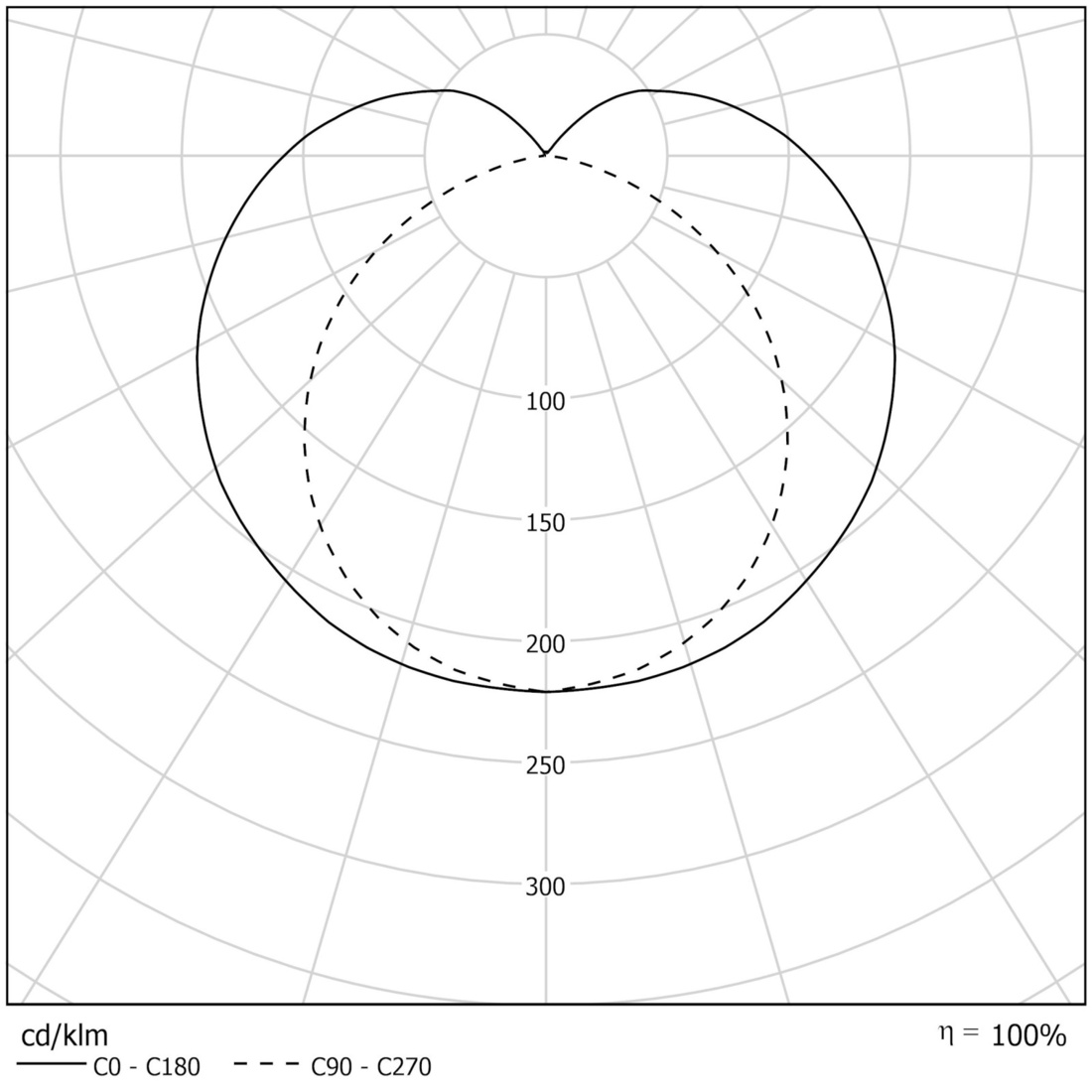

| Optics |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Gaskets |

|

| Method of construction |

|

| ATEX / IECEx |

|

| Marking |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|

|